Company advertising board book printing and binding

| Min. Order: | 500 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 300,000pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Hardcover Book, Brochure, Catalog, Softcover Book, Magazine |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Content: | Catalogue |

| Style: | Others |

| Intended Audience: | Adults |

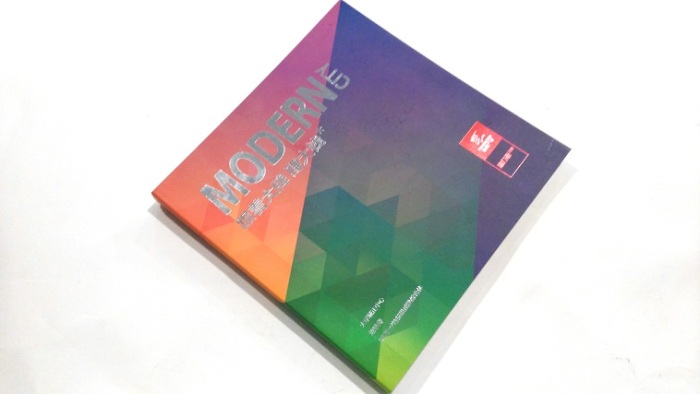

| Brand Name: | Xiandai |

| Size: | 11X8.5" |

| Cover: | Two plies of paperboards |

| Paperboard: | 2mm |

| Finishing: | Gloss silver stamping&mounting |

| Cover paper: | Kraft paper |

| Color: | full color |

| Printing process: | offset printing |

| Paper thickness: | 100pt |

| Purpose: | Company advertising |

| Binding: | Board binding |

| Production Capacity: | 300,000pcs/month |

| Packing: | packed in plastic bag and carton |

| Delivery Date: | 7-10 days after order confirmation |

Product Description

Company advertising board book printing and binding

This board book is a custom company advertising board book printed for property company, which is mainly applied for sales promotion.

This board book has silver stamped cover, 1.5mm thick panel for inside pages and board binding mode, etc.

Description | 1.5mm thick panel board book |

Material | Paperboard |

Size | 8.5X11" |

Cover | Paperboard |

Surface Finishing | Die cutting, silver stamping and mounting |

Cover of board book:

Inside pages of board book:

1.5mm thick panel:

Gloss silver stamping on board book cover:

Color control procedures:

The color of our digital sample is 95% similar to that of printed sample on Heidelberg printer. They are put in our strict color management system. We can supply a whole set of digital printing sample for your reference. Of course, you can see its final binding effects after receiving this digital sample. It can be finished within three days.

We ensure the color consistency through our advanced Koda CTP system and strict color management procedures from pre-press to printing on the printer.

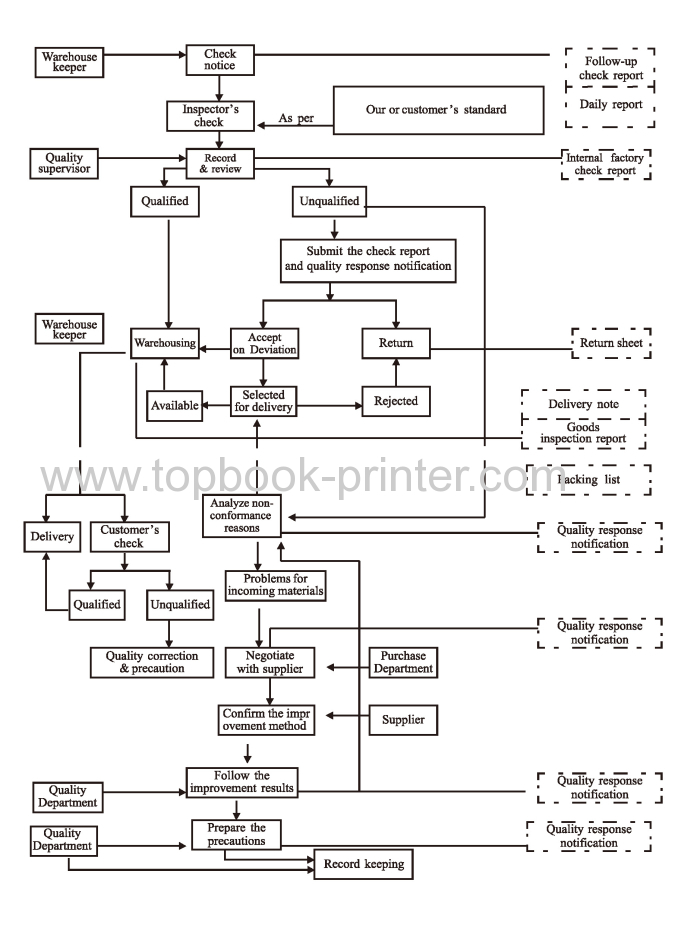

Quality control flowchart:

We have implemented strict 6S manufacturing system and ISO9001 quality assurance system. There are 12 QC inspectors and engineers, and all the products have to be inspected before leaving the factory (100% inspected).

Production:

Step 1: Cut boards

Cut desired-size boards from pressed cardboard. I used an illustration board but any pressed (not corrugated) cardboard will do. You'll need enough for the interior pages, plus the front and back cover. Round two of the corners.

Step 2: Print interior pages

Print the images on adhesive paper, one for each pair of facing pages. The first image will be the inside of the front cover and the first page; the next is the second and third page, etc. I used Avery full sheet labels for this. Keep any content away from the edge. Cut down each sheet to roughly the size of the image.

Step 3: Mount interior pages

Peel of the backing from the first sheet and lay it face down. Place two boards on top, lining them up with the center of the sheet.

Trim off the excess adhesive paper using a sharp knife.

Continue mounting all interior pages, using the back of the previous page for the front of the next.

Step 4: Print cover

Measure the thickness of the book so far. Determine the size of the image for the front cover, plus the thickness of the book, plus any border. The image should be, from left to right, the back cover, the spine and the front cover.

Print the image on adhesive paper. Crease the paper along the edges of the spine.

If you can't print a single image large enough for the entire cover, you can print it in two pieces, overlapping on the spine.

Step 5: Mount cover

Peel the backing off the cover sheet and lay it face down. Cut two strips of heavy paper (card stock), each the width of the spine. Press them onto the adhesive paper, one along the spine, one next to it on the back cover.

Set the book on the cover, lining up the spine. Wrap the front and back cover around the book. Trim off any excess paper. When the book is opened, the cover should pull away from the book along the spine and a narrow strip of the back cover.