Japanese favourite screw and barrel for extruder from Chinese industrial factory

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100T/WEEK |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screw And Barrel |

Product Detail

| Model No.: | LFm45-90 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Plastic Type: | Others |

| Use: | Others |

| Shaft Design: | Others |

| Brand Name: | LF |

| Category: | Scew and barrel |

| Material: | 38CrMoALA |

| Application: | Single screw extruder |

| Scope of application: | PP PE PVC PET PS PPR etc. |

| Linearity: | 0.015 |

| Surface hardness: | HV1100 |

| Surface roughness: | 0.4 |

| Diameter: | Customizable |

| After-sales service: | one year warranty |

| Production Capacity: | 100T/WEEK |

| Packing: | Standard packing:plastic film and plywood box |

| Delivery Date: | Within 15 days |

Product Description

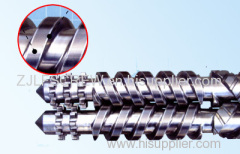

Japanese favourite screw and barrel for extruder from Chinese industrial factory

Product Description

Specifications of screw and barrel for extruder

| Material | 38CrMoALA,42cmO, SKD61 |

| Diameter | 15mm-360mm |

| L/D | 15mm-45mm |

| Alloy depth | 0.8mm-2.0mm |

| Nitridation hardness | HV900-1000 |

| Nitridation fragility | less than grade 2 |

| Surface roughness | Ra0.4μm |

| full hard screw | HPT1,HPT2,HPT3 |

| Heat treatment | Nitriding treatment, hard chrome plating, high-frequency quenching, Spray coating corrosion resistance, Wear-resisting double metal layer, vacuum hardening |

Quality of screw and barrel for extruder

Different kinds of screw and barrel are all made of high-quality alloy steel 38CrMoALA, with professional equipment and finishing treatment, the product will have the characteristics of wear-resistance and corrosion resistance, as well as prolong life-span after nitriding, which can instead of some imported goods. All soeicfications are strictly according to JB/T8538-1991 and ISO9002.

In addition, the compression of Screw and barrel can be designed according to different product and formula.

Company info of screw and barrel for extruder

At present, we are the designer, manufacturer, product seller, and also provide the after-sale service. With ten years experience, we have advanced processing equipment, perfect testing method, specialized in manufacturing various kinds of extruder machine,plastic collosol machine, screw&barrel and accessories. we also manufacture the conical double screw & barrel and parallel double screw & barrel which are applied to tubular product, section bar, plate extruding and pelletizing. Always keeping a high quality in the same products, linear processing has been in the position of international advanced level .

Detail Pics of screw and barrel for extruder

Company Information

With over 10 years of production, LIFENG Machine offers a full line of screw, barrel and assembly parts for injection/ extrusion molding machine.

Quality check is the last stage before deliver the goods to customer and the most important stage in our production process. Therefore, in order to carry out our target of achieving zero defects, strict quality check is conducted at every stage of the production. Start from the designing, manufacturing and up to final stage of packing, strict quality check is carried out. This is to ensure that only goods of high quality are delivered to our customers.We can offer you different standard of screws and barrels.In case any enquiry of our production or any question,design plan and quotation, don't hesitate to contact me or visit our website atwww.zjlf-China.com

Not only we are offering high quality products, we also provide depth information about how to use our products.

No minimum orders, 100% guarantee, full warranty. Quantity break pricing.

Packing and Shipping

Contact us