220MM Electric Generator Progressive Stamping High Speed Motor Core Die

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | CIF |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 200 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

| Main Products: | 110-95 Refrigerator Progressive Stamping Motor Core Die, 102-90 Refrigerator Progressive Stamping Motor Core Die, 108mm Wahser Progressive Stamping High Speed Motor Core Dies, 168MM Industrial Progressive Stamping High Speed Motor Core Die, 142mm Refrigerator Progressive Stamping High Speed Motor Core Dies |

Product Detail

| Model No.: | 220 Electric Generator Motor Core Die |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Product: | Others |

| Product Material: | Steel |

| Shaping Mode: | Punching Mold |

| Brand Name: | GSTMOLDING |

| Production Capacity: | 200 |

| Packing: | wooden |

| Delivery Date: | 80 days |

Product Description

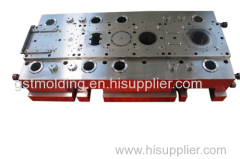

220mm Electric Generator Progressive Stamping High Speed Motor Core Die

First,Briefly Introduction of Electric Generator Progressive Motor Core Die

Our Electric Generator Progressive Stamping High Speed Motor Core Die designed and fabricated for heavy producing of motor cores for Electric Generator Machine motor manufacturing. With material, silicon

steel thickness of which is 0.3mm--1.0mm, we design, produce, test-run, ship and setting up service for Electric Generator Progressive Stamping High Speed Motor Core dies.

Main Technical Parameters of Electric Generator Progressive Stamping High Speed Motor Core Dis:

| No | Item | Main Technical Information | No | Item | Main Technical Information |

| 1 | Total Life | >200 million strokes | 12 | Tryout speed | 200 Strokes Per. Min. |

| 2 | Regrinding Life | > 2 million strokes/0.1mm | 13 | Normal Speed | 200-350 Strokes Per. Min. |

| 3 | Available height of blade | > 10mm | 14 | Concentricity | ≤ 0.05MM |

| 4 | Material of blade | KG4 ( Carbide ) | 15 | Burr | ≤ 0.05MM |

| 5 | Type of inlay | According to the design | 16 | Die Set Structure | Three Plate cages |

| 6 | Guide Assembly | Precision and high hardness | 17 | Guide Assembly | High Precision and hardness |

| 7 | Standard parts | MISUMI ( Japan ) | 18 | Lam.Delivery from the die | Guide Cage excluded |

| 8 | Safe-guarding | Feeding Error Protector | 19 | Spare parts | About 30% of total wearout in the die |

| 9 | Rotor Twisting Type | Worm Gear + Worm Bar | 20 | Punch and die process | wiring cutting + curve grinding |

| 10 | Tape Slots control Type | Motor + Twisting control panel | 21 | Die position & shape precision | ≤ 0.005mm with 1000mm |

| 11 | Product outlet type | By Convery | 22 | Safety device | misfeeding inspection and height limted column |

Second: We have advanced and precise machinery tooling for Electric Generator Progressive Stamping High Speed Motor Core Die Fabrication such as:

Electrical Discharge Machining ( EDM) --- Possible to make fine holes dia. 0.1mm

Wire EDM ---- Possible to make fine shapes by using fine wire dia. 0.05mm

Profile Grinding --- Guarantee parts accuracy by precision profile grinding

Third: Various Electric Generator Progressive Stamping High Speed motor core die

Fourth: Typical Electric Generator Progressive Stamping High Speed Motor Core Picture for reference

Thank you and do not hesitate to contact us freely if you have any question for Electric Generator Progressive High Speed Stamping Motor Core Die.