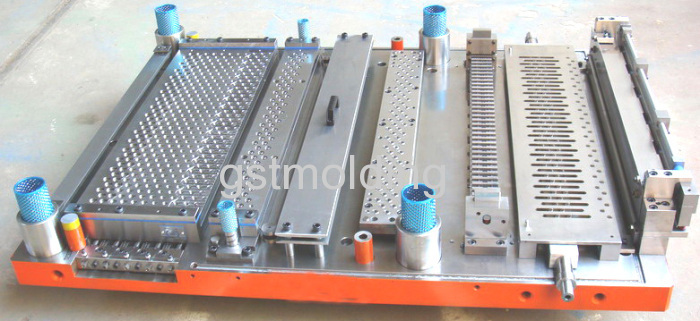

Fin Press Die with Progressive Ribbon Type for fin production 9.52 x 25 x 21.65 x 24rows

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 500 |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

| Main Products: | 110-95 Refrigerator Progressive Stamping Motor Core Die, 102-90 Refrigerator Progressive Stamping Motor Core Die, 108mm Wahser Progressive Stamping High Speed Motor Core Dies, 168MM Industrial Progressive Stamping High Speed Motor Core Die, 142mm Refrigerator Progressive Stamping High Speed Motor Core Dies |

Product Detail

| Model No.: | 9.52 x 25 x 21.65 x 24 R x 2P |

|---|---|

| Means of Transport: | Ocean, Air |

| Product: | Others |

| Product Material: | Steel |

| Shaping Mode: | Punching Mold |

| Brand Name: | GSTMOLDING |

| Production Capacity: | 500 |

| Packing: | wooden |

| Delivery Date: | 80 days |

Product Description

Progressive Fin Die Φ9.52 x 25mm x 21.65mm x 24 Rows x 2P is core element equipment for high thermal efficient finned coil heat exchangers, the configuration of the corrugation profiles, enhancement of louver or lance as well as the quality of collar will affect heat exchangers performance.

GST Molding design and develop fin die with high quality materials and correct heat treatment which warrants fin dies can consistently produce high quality fins meet and access the demand, We can offer various fin surface configurations such as Plain, Sine Wave, V Wave, with enhancement as louver or lance, As well as fin holes diameters are range from 4mm to 25.4mm, what's more, Oval fin holes pattern also widely offered. So many optional items are available for customer option.

progressive ribbon type high speed fin die consist of a 6 station draw, pierce extrude, reflare, edge trim, slit, feed, and cutoff station. The fin surface is accomplished in the last draw station by removable plate, the die stays in the press during plate changes.

progressive ribbon type high speed fin die features the latest version of draw station adjustment. Each station can be individual adjusted using a dial. The draw dials are calibrated, as is the reflare adjustment dial. Our digital position indicator design will be included on all draw and reflare dials, which greatly improves the visibility and ease of adjustment. These features allow for extremely fast changes from one collar setting to another.

Hollar highe adjustment range from 10--18 FIN PER INCH.

Fin die speed 200RPM -- 300RPM

Aluminum material thickness 0.15mm.

V wave fin surface without any enhancement.

Ripple Slit cutting .

Optional Features progressive ribbon type high speed :

Arrangement Pattern in Stagger or Inline

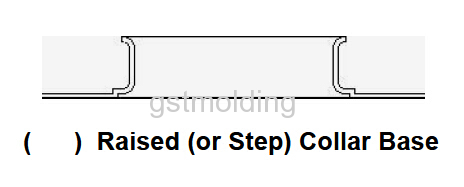

There is also many collar base for choice: Conical Collar base; Raised or step collar base and flat base

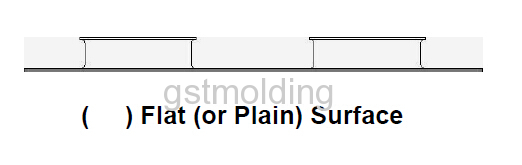

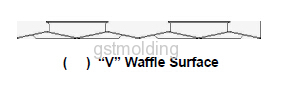

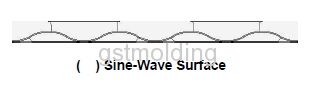

There is many fin surface for option such as V waffle surface, Sine Waffle surface:

Flat or plain fin surface progressive ribbon type high speed fin die

"V" Waffle Surface progressive ribbon type high speed fin die desgin-----

Sine-Wave surface progressive ribbon type high speed fin die design type

For more details for progressive ribbon type high speed fin die or fin dies, Please contact us freely

Thank you