plastic cap lining machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 50 sets per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Plastic Cosmetic Round Airless Lotion Bottle With Pump, Battenfeld Parallel Twin Screw Barrel And KMD Parallel Twin Screw Barrel And Cincinnati Parallel Twin Screw Barrel, Extrusion Screw And Barrel For Extrusion Machine, Bimetallic Screw And Barrel For Injection Molding Machine, 9 Feet Plastic Pallet |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Processing: | Packing Machine |

| Automatic Grade: | Automatic |

| Type: | General |

| Usage: | Others |

| Packaging: | Metal |

| Min. Cap diameter: | 18mm |

| Max. cap diameter: | 60mm |

| Min. cap height: | 15mm |

| Max. cap height: | 25mm |

| Capacity: | 12000-15000 pcs |

| Production Capacity: | 50 sets per month |

| Packing: | wooden case |

| Delivery Date: | 30 days |

Product Description

Specifications

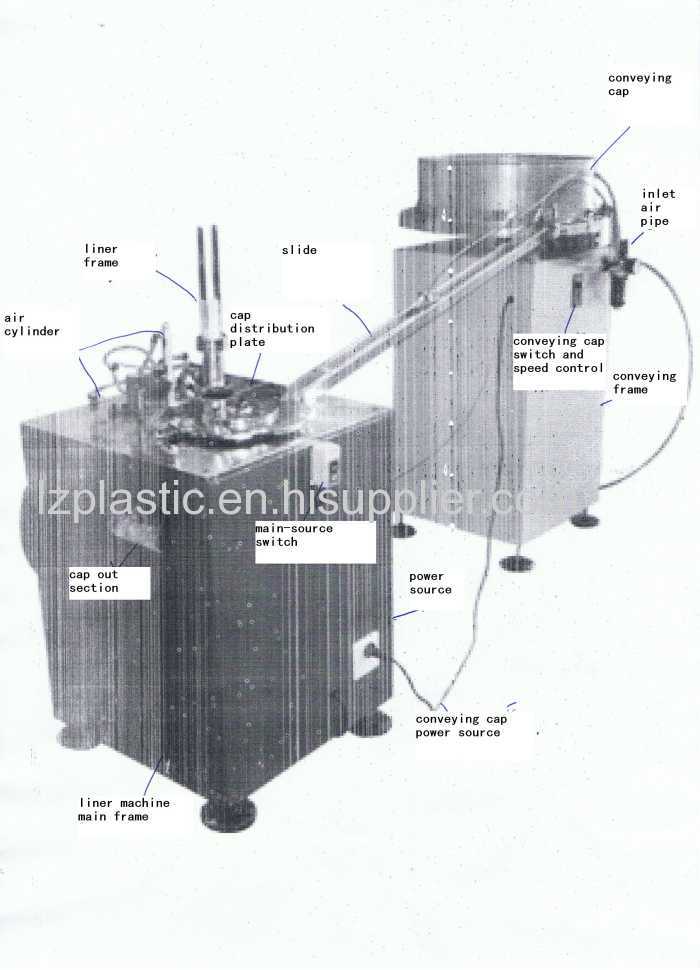

This Cap liner molding machine is used for processing gasket/liner for plastic bottle cover /cap

speed 10000-18000pcs/hour

Plastic bottle cover dropping plastic machine( molding machine for plastic gasket)

1> The dropping plastic machine is mainly used for processing of sealing gasket for plastic bottle cover to make the sealing structure to reach the requirements of reasonable standard. Its technological process is that, through liquefying at high temperature, the raw material of domestic and imported TPE plastics is molded into the internal gasket of plastic cover, such processing possesses the action of air pressure-proof, retaining freshness and preserving taste and is suitable for the bottle cover processing of aerated water, tea beverage, fruit juice beverage etc, series products.

With reasonable design, the machine has the functions of putting cover in proper order, delivering cover, forming, temperature controlling, frequency-changing and speed-regulating etc. With automatic processing it can save a great deal of labor and time, heighten greatly production efficiency and is an essential equipment to realize production in batch for plastic bottle cover manufacture. It conforms to the standard of food hygiene and possesses the same performance.

2> Technical parameters:

Rotating type: 10000-18000pcs/hour

Gasket weight: 0.25-0.4g/gasket

Working gas pressure:0.4 MPA

Total power consumption:12KW

Contour dimensions:2500 x1000 x 1500mm

Machine weight: 2000KG