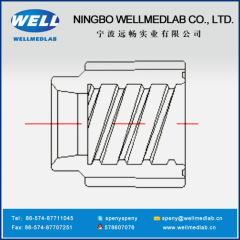

Edible oil bottle caps injection mould

500.0~1000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 45 sets per week |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Plastic Cosmetic Round Airless Lotion Bottle With Pump, Battenfeld Parallel Twin Screw Barrel And KMD Parallel Twin Screw Barrel And Cincinnati Parallel Twin Screw Barrel, Extrusion Screw And Barrel For Extrusion Machine, Bimetallic Screw And Barrel For Injection Molding Machine, 9 Feet Plastic Pallet |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Product: | Vehicle Mould |

| Product Material: | Steel |

| Shaping Mode: | Blowing Mould |

| Brand Name: | lianzhong |

| port: | ningbo |

| cavity: | single or multi |

| cavity material: | P20,2316,S136,,#50,#60,3cr13 ect |

| machining: | cnc,grinding etc |

| product material: | PET,PP,PE,PVC ect |

| mould life: | 2-3 million shot |

| Production Capacity: | 45 sets per week |

| Packing: | wooden case |

| Delivery Date: | 30 days |

Product Description

We are a mould factory located in Huangyan district Zhejiang province--the hometown of the mould in China,We specialize in plastic bottle mould,preform mould,cap mould,injection mould,water bottle mould,mineral bottle mould,shampoo and costmetic bottle mould,fruit juice bottle mould,oil bottle mould,jar mould,barrel mouold,injection machine,blowing bottle machine,blow moulding machine,injection machine and so on with modern technology and advanced equipments.For ten years diligent operation,we had established a mature one-stop service line from inquiry to after-sales service.

Our cap mould features:

| 1.· Mold cavity from 1 to 48. |

| 2.· Adopt imported high-quality mold steel(# P20 steel and #2316 Steel Germany,#718,#s136 and so on). |

| 3.· Adopt advanced hot runner system with point to point control system,which ensures uniform heating. |

| 4.· Each core and cavity adopt independented cooling system, which brings high productivity. |

| 5.· Mold cavity is replaceable,which is convenient to change the label. |

| 6.· At least 3 million shots life-time guaranteed. |

| 7.· Electric control system with simulating stretch testing to improve yield rate. |

| 8.· The materials of core and cavity are made of mirror corrosion resistance and plastic mold steel imported from Sweden or Germany. |

| 9.· International standard screw neck, imported nitrided steel with high hardness and long life time. |

| 10.· Adopt advanced hot runner system with point to point control system,ensure uniform heating,which brings high-quality products. |

| 11.· Valves gate mold without tail,reduce the labor force. |

| 12.· Spare parts are processed by CNC,which ensure the precision. |

| 13.· Adopt advanced technique to make each cavity self-lock,and ensure mold concentricity(tolerance less than 0.08mm). |

| 14.· · Design different kinds of mold structure,such as sliting cap mould and cuting cap mould etc. |

| 15.·Great final polish |

.jpg)