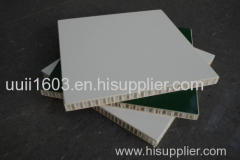

Fiberglass Honeycomb Composite Panel

| Payment Terms: | L/C, T/T |

|---|---|

| Place of Origin: | Guangdong |

Company Profile

| Location: | Huizhou, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Etc, Coach And Commercial Vehicle Outer Skin FRP Sheet Without Gelcoat, Composite FRP Sandwich Panels, FRP Sheet And Coil, FRP Sheet Without Gelcoat Fiberglass Sheet Without Gelcoat Fiberglass Sheet Fiberglass Skin For Vegicle |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Packing: | export standard |

| Delivery Date: | 7-10days |

Product Description

Fiberglass and PP honeycomb sandwich panel

1. Introduction:

A. The panel are make of prefabricated fiberglass reinforced plastic sheet, high-strength woven roving and plastic honeycomb by vacuum bounding in high pressure from Germany technique.

B. The gelcoat on the surface is of iso-phtalic-ngp based resin, FDA approved

2. Advantage

A. better insulation

B. Light weight

C.High Strength

D. Corrosion resistance

E.Glossy and smooth surface

F. Easy repair

G. Long life using.

It's the first choice to modern logistics

3. Standard thickness: 15mm, 18mm, 21mm

4. Dimension of panel(Max): 10m* 3m

We are a Stocking Distributor for Sequentia Corrugated Fiberglass Sheets Panels & Sheet, Fiberglass corrugated roofing panels, Sequentia Structoglas FRP Wall Liner Panels and Moldings.

We can produce over 500 corrugated profiles

FRPs are commonly used in the aerospace, automotive, marine, construction industries and ballistic armor

Truck Body Panels

Honeycomb sandwich panels are widely used in the Truck Body manufacturing industry due to their significant weight and cost advantages compared to full bodied alternatives.

Here are the types of panels, that are most commonly used for Truck Bodies:

1.Fiberglass Reinforced Plastic (FRP) Composite panels with Poly Propylene (PP) Honeycomb core

2.FRP Composite panels with Plywood core

3. FRP Composite panels with XPS foam core.

There are multiple possibilities for different combinations of core and skin materials, depending on the project requirements and customer's preferences.

The Honeycomb Composite Panel weighs approximately 5.5-8.5 kg/m2, depending on the surface skin and thickness.

Maximal single panel size:

3000 x 12000 mm

Features:

• Superior impact and damage resistance

• Surfaces that do not corrode, fade or peel

• Superior acoustic and thermal insulation

• Smooth wall surfaces that easily allow graphics and paint application

•Minor damage are easily repaired with standard fiberglass fillers

Our products are of good quality with competitive price ,for more details ,visit us at http://www.compositefrpsheet.com

.gif)