electric shut -off ball valve

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 50-100 each month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Shaoxing, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Pressure Single Seat Control Valve, Penumatic Linear Control Valve, Pneumatic Control Butterfly Valve, Pneumatic Cage Type Regulating Valve, Self Acting Control Valve |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Power: | Others |

| Standard or Nonstandard: | Standard |

| Pressure: | High Pressure |

| Structure: | Control |

| Material: | Stainless Steel |

| Temperature of Media: | Normal Temperature |

| Media: | Gas |

| Brand Name: | TISUN |

| functions:: | for control |

| Exp Region:: | America, UN, east asia,mideast etc . |

| products:: | pressure control valve |

| Temperature:: | -196℃-570℃(double seat) |

| actuator:: | pneumatic diaphtagm actuator |

| shut-off class:: | ASME B 16.104V |

| Production Capacity: | 50-100 each month |

| Packing: | WODDEN CATTON |

| Delivery Date: | as per the quantity(15-25 days) |

Product Description

electric 0-off ball valve electric actuator and ball valve type 0 DN15 ~ 200 floating ball, DN250 ~ 300 is fixed ball structure.

The valve compact structure, small size, light weight, easy assembly and disassembly maintenance, flow through Young, small flow resistance, good sealing performance. The seat is flexible lip structure, with automatic wear compensation and relief role in the cavity, and therefore reliable sealing and long service life.

Widely used in petroleum, chemical, electric power, metallurgy, steel, paper, pharmaceutical, food, textile, light industry and other industries.

Technical parameters and performance

Body

Type | Straight ball valve casting |

DN | DN15,20,25,32,40,50,65,80,125,150,200,250,300 |

Nominal | PN1.6,2.5,4.0,6.4MPa |

Flange Standard | JB/T79.1(2)-94,GB/T9113.1(2)-2000 |

Material | Cast ZG (230-450), cast stainless steel (ZG1Cr18Ni9Ti, ZG1Cr18Ni12Mo2Ti) |

Cover on foot | Integral with the valve body into a -45 ~ 400 ℃ |

Gland Type | Bolt Clamp |

Packing | V-type PTFE packing, PTFE impregnated asbestos packing, asbestos textile packing, graphite packing |

Valve components

Spool type | Ball spool |

Flow characteristics | The quick opening |

Material | Cast stainless steel (ZG1Cr18Ni9Ti, ZG1Cr18Ni12Mo2T) |

Rated travel | Full 90 ° |

Executive body

type | 3410R,PSQ,HQ Electronic electric actuator |

Input Signal | 1-5V·DC |

Supply Voltage | 220V/50HZ |

Ambient temperature | -20~+70℃ |

Body, trim material combinations and standard temperature range

R.TFE (F): two molybdenum reinforced PTFE

R.TFE (C): Carbon fiber reinforced PTFE

HCr: hard chrome plating

S.S: part surfacing Stellite

Body | ZG230-450,ZG1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti | |||||

Ball core | Material | 304 | 304 | 304 | 316 | 316 | 316 |

Process | Polishing | Polishing | Spray, polish | Polishing | Polishing | Spray, polish | |

Stem | Material | 304 | 304 | 304 | 316 | 316 | 316 |

Seat | Material | R.TFE(F) | R.TFE(F) | 304,316 | R.TFE(F) | R.TFE(F) | 316 |

Process | - | - | S.S | - | - | S.S | |

Leakage class | VI | VI | IV | VI | VI | IV | |

Temperature | 2G3230-450 | -5~+180 | -5~+250 | -5~+400 | -5~+180 | -5~+250 | -5~+400 |

ZG1Cr18Ni9Ti ZG1Cr18Ni12Mo2Ti | -45~+180 | -45~+50 | -45~+400 | -45~+180 | -45~+250 | -45~+400 | |

Structure

Actuator configuration, allowing the pressure

DN | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |||||

Executive body | 3410RSA-05 | 3410RSA-10 | 3410RSA-20 | 3410RSA-50 | 3410RSA-60 | 3410RSA--100 | ||||||||||||

△P(100KPa) | 64 | 64 | 64 | 64 | 64 | 64 | 64 | 63 | 58 | 34 | 17 | 15 | 12 | |||||

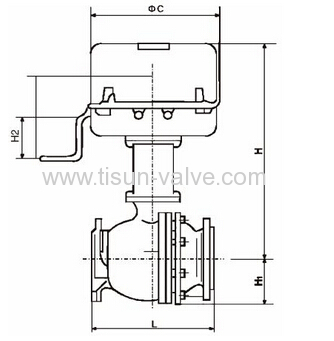

Dimensions

Unit:mm

DN | L | H | H1 | ΦC | H2 | ||

PN16 | PN40 | PN16 | PN40 | ||||

15 | 130 | 140 | 310 | 45 | 47.5 | 225 | 160 |

20 | 130 | 152 | 310 | 49 | 58.5 | 225 | 160 |

25 | 140 | 165 | 330 | 55 | 62.5 | 225 | 160 |

40 | 165 | 190 | 350 | 65 | 77.5 | 225 | 160 |

50 | 203 | 216 | 360 | 75 | 82.5 | 225 | 160 |

65 | 222 | 241 | 435 | 90 | 95 | 225 | 160 |

80 | 241 | 283 | 445 | 95 | 105 | 335 | 160 |

100 | 305 | 305 | 480 | 115 | 127.5 | 335 | 160 |

125 | 356 | 381 | 480 | 127 | 140 | 335 | 160 |

150 | 394 | 403 | 595 | 140 | 160 | 335 | 160 |

200 | 457 | 502 | 615 | 172.5 | 190 | 335 | 160 |

250 | 533 | 568 | 875 | 310 | 310 | 335 | 160 |

300 | 610 | 648 | 950 | 350 | 350 | 335 | 160 |

Ordering Information

Please fill out when ordering "specifications" or indicate the following:

First, if the order has not been pre-selected models, please provide us your parameters

1, nominal diameter, rated flow coefficient Kv

2, fluid properties (including nominal pressure, temperature, viscosity or pH)

3, a valve in the form of (power - off type or electric - open)

4, the flow characteristics

5, before the valve, the valve pressure

6, valve, valve material

7, the input signal

8, with an attachment, annex models, so that we can correct for your selection.

Second, the special requirements

A special inspection

2, fully to oil, to water treatment;

3, cut copper processing;

4, a special interface, the pipe;

5, under vacuum conditions;

6, designated coating color

7, special media (oxygen, chlorine, hydrogen);

8, the use of stainless steel fittings;

Third, if the company has been selected by the design of the product model, please order directly from our sales department by model.

Please try to provide design drawings and detailed parameters by our experts for your audit checks.

.jpg)

.jpg)