valve ZDLM electric control valve

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 50-100 each month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Shaoxing, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Pressure Single Seat Control Valve, Penumatic Linear Control Valve, Pneumatic Control Butterfly Valve, Pneumatic Cage Type Regulating Valve, Self Acting Control Valve |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Power: | Others |

| Standard or Nonstandard: | Standard |

| Pressure: | High Pressure |

| Structure: | Control |

| Material: | Stainless Steel |

| Temperature of Media: | Normal Temperature |

| Media: | Gas |

| Brand Name: | TISUN |

| functions:: | for control |

| Exp Region:: | America, UN, east asia,mideast etc . |

| products:: | pressure control valve |

| Temperature:: | -196℃-570℃(double seat) |

| actuator:: | pneumatic diaphtagm actuator |

| shut-off class:: | ASME B 16.104V |

| Production Capacity: | 50-100 each month |

| Packing: | WODDEN CATTON |

| Delivery Date: | as per the quantity(15-25 days) |

Product Description

electric control valve sleeve, an adjusting instrument input (4-20mA DC, 0-10mA DC or 1-5V DC) control operation can be a control signal and power supply, automatic control on the process of fluid pipeline. Process parameters are widely used in precise control of gas, liquid medium, steam and other parameters such as pressure, flow, temperature, liquid level, maintained at a given value, is common in accordance with the IEC standard valve products. Two seat valve has the unbalanced force is small, allowing a large pressure difference, flow capacity, is suitable for leakage is not strict, pressure clean medium large occasions, widely used in electric power, metallurgy, chemical industry, petroleum, environmental protection, light industry, equipment industry.

| DN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | ||||||

| Seat diameter mm | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | ||||||

| Rated number Kv | 10 | 16 | 25 | 40 | 63 | 100 | 160 | 250 | 400 | 630 | 1000 | 1600 | 2000 | 2700 | ||||||

| Nominal pressure(MPa) | 1.6,2.5,4.0,6.4,10 | |||||||||||||||||||

| Trip(mm) | 16 | 25 | 40 | 60 | 100 | 130 | ||||||||||||||

| Flow characteristics | Linear, equal percentage, quick opening | |||||||||||||||||||

| Working temperature ℃ | -40~+230 ℃ (Chang Wenxing), fin type +230~+450 ℃ (medium temperature) special orders | |||||||||||||||||||

| Flange size | According to JB/79.1 (2) -94, HG20592-97, GB, ANSI, JIS, DIN and other standards | |||||||||||||||||||

| Body material | WCB, 304, 316, WC6, WC9, nickel, titanium, Hastelloy, Monel etc. | |||||||||||||||||||

| Valve material | 304, 316, 420, nickel, titanium, Hastelloy, Monel etc. | |||||||||||||||||||

The valve type | Through two seater casting ball valve | |||||||||||||||||||

The valve cover type | Ordinary type (room temperature), hot chip (temperature) | |||||||||||||||||||

| The electric actuator | PSL-202 | PSL-204 | PSL-208 | PSL-312 | PSL320 | PSL325 | ||||||||||||||

| 361L | 361LSA-20 361LSA-20 | 361LSB-30 361LXB-30 | 361LSB-50 361LXB-50 | 361LSC-65 361XC-65 | 361LSC-99 361LXC-99 | 361LSC-160 361LXC-160 | ||||||||||||||

2 electric sleeve valve technical parameters

| DN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | ||

| Seat diameter mm | 26 | 32 | 40 | 50 | 66 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | ||

| Rated | Linear | 11 | 17.6 | 27.5 | 44 | 69 | 110 | 176 | 275 | 440 | 690 | 1000 | 1600 | |

| The percentage of | 10 | 16 | 25 | 40 | 63 | 100 | 160 | 250 | 400 | 630 | 900 | 1440 | ||

| Nominal pressure (MPa) | 1.6,2.5,4.0,6.4,10 | |||||||||||||

| Trip (mm) | 16 | 25 | 40 | 60 | 100 | |||||||||

| Flow characteristics | Linear, equal percentage, quick opening | |||||||||||||

| Working temperature ℃ | -40~+230 ℃ (Chang Wenxing), fin type +230~ ten (450 ℃ temperature type), a special order | |||||||||||||

| Flange size | According to JB/79.1-94, HG20592-97, GB, ANSI, JIS, DIN and other standards | |||||||||||||

| Body material | WCB, 304, 316, WC6, WC9, nickel, titanium, Hastelloy, Monel etc. | |||||||||||||

| Valve material | 304, 316, 420, nickel, titanium, Hastelloy, Monel etc. | |||||||||||||

The valve type | Through single seat casting ball valve | |||||||||||||

The valve cover type | Ordinary type (room temperature), hot chip (temperature) | |||||||||||||

| The electric actuator | PSL | PSL-202 | PSL-204 | PSL-208 | PSL-312 | PSL-320 | ||||||||

| 3611 | 361LSA-20 361LXA-20 | 361LSB-30 361LXB-30 | 361LSB-50 361LXB-50 | 361LSC-65 361LXC65 | 361LSC-99 361LXC-99 | |||||||||

Note: the company produced the largest diameter to DN400 sleeve valve.

Technical parameters of electric actuator

| Model | Rated output power N | Speed mm/s | Technical parameters | ||||

| PSL | 361L | PSL | 361L | PSL | 361L | PSL | 361L |

| 201 | 361LSA-08 361LXA-08 | 1000 | 800 800 | 0.25 | 4.2 4.2 | ||

| 202 | 361LSA-20 361LXA-20 | 2000 | 2000 2000 | 0.50 | 2.1 2.1 | Power supply: AC220V 50HZ Input signal: DC4-20mA DC1-5V (shielding line signal line) Output: DC4~20mA Protection grade: IP67 With the handwheel | Power supply: AC220V 50Hz Input signal: DC4-20mA DC1-5V (shielding line signal line) Output: DC4~20mA Protection grade: IP65 Flameproof mark: Exd ll BT4 With handle |

| 204 | 361LSB-30 361LXB-30 | 4500 | 3000 3000 | 0.50 | 3.5 3.5 | ||

| 208 | 361LSB-50 361LXB-50 | 8000 | 5000 5000 | 1.00 | 1.7 1.7 | ||

| 312 | 361130-65 | 12000 | 6500 | 0.60 | 2.8 | ||

| 320 | 361LSC-99 | 20000 | 10000 | 1.0 | 2.0 | ||

Note: other optional electric actuator Siemens: Yangzhou, UK and other performance indicators

Project | Index value | ||

The basic error % | With 361L±2.5;With PSL±1.0 | ||

| The return difference % | With 361L 2.0;With PSL 1.0 | ||

| The dead zone % | With 361L 3.0;WithPSL 1.0 | ||

| Always point bias % | Electric drive | The starting point | ±2.5 |

| Finish | ±2.5 | ||

| Power off | The starting point | ±2.5 | |

| Finish | ±2.5 | ||

| Always point bias | 50:1 | ||

| Rated stroke deviation % | ±2.5 | ||

| Leakage L/H | According to JB/T7387-94 IV less than the valve rated capacity of X 10-4 | ||

To allow pressure

| DN | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | |||||||||||

| Seat diameter (mm) | 10 | 12 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | ||||||

| Actuator | To allow pressure△P(MPa) | |||||||||||||||||||

| With PSL | PSL202 | 6.4 | 6.4 | 6.4 | 4.90 | 3.14 | 1.92 | 1.23 | 0.78 | |||||||||||

| PSL204 | 4.31 | 2.76 | 1.76 | 1.04 | 0.69 | 0.44 | ||||||||||||||

| PSL208 | 1.86 | 1.23 | 0.78 | 0.50 | 0.35 | 0.20 | ||||||||||||||

| PSL320 | 1.26 | 0.87 | 0.49 | |||||||||||||||||

| With 361L | 361LSA-20 | 6.4 | 6.4 | 6.4 | 4.90 | 3.14 | 1.92 | 1.23 | 0.78 | |||||||||||

| 3611SB-50 | 4.79 | 3.06 | 1.96 | 1.16 | 0.76 | 0.49 | ||||||||||||||

| 3611SC-65 | 1.51 | 0.99 | 0.64 | 0.41 | 0.28 | |||||||||||||||

| 3611SC-99 | 0.63 | 0.44 | 0.25 | |||||||||||||||||

1, the electric single seat valve to allow pressure

Note: the actual configuration should be determined according to the process parameters. If the maximum working pressure exceeds the range on the table, please contact with me.

2, electric sleeve valve to allow pressure

| DN | 25 | 50 | 65 | 80 | 100 | 200 | 250 | 300 | |||||

| Seat diameter (mm) | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

| Actuator | To allow pressure△(Mpa) | ||||||||||||

| With PSL | PSL204 | 6.4 | 6.4 | 6.4 | 5.1 | 6.4 | |||||||

| PSL204 | 6.4 | 5.62 | |||||||||||

| PSL208 | 6.4 | 5.31 | 3.97 | ||||||||||

| PSL320 | 6.4 | 4.14 | |||||||||||

| With 361L | 361LSA-20 | 6.4 | 6.4 | 6.4 | 6.4 | 6.4 | |||||||

| 361LSB-50 | 6.4 | 6.25 | |||||||||||

| 361LSC-65 | 6.4 | 4.32 | 3.23 | ||||||||||

| 361LSC-99 | 3.31 | 2.7 | |||||||||||

Note: the actual configuration should be determined according to the process parameters. If the maximum working pressure exceeds the range on the table, please contact with me.

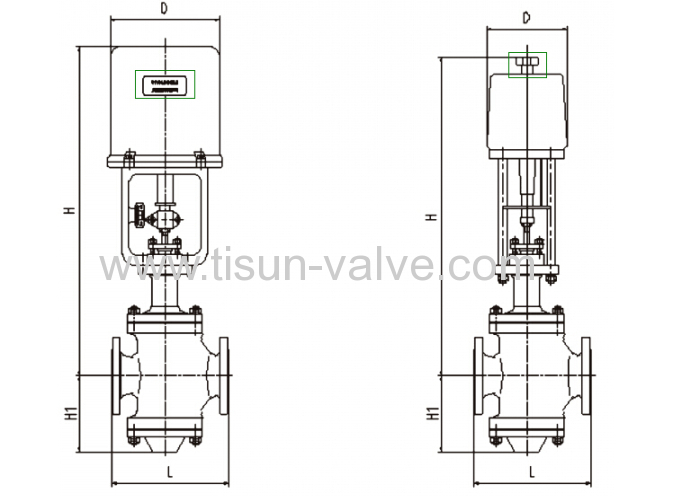

Company :mm

| Seat diameter | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | |||||||||||

| L | PN16 | 187 | 184 | 222 | 254 | 276 | 298 | 352 | 451 | 600 | 673 | 737 | ||||||||||

| PN40 | 194 | 197 | 235 | 267 | 292 | 317 | 368 | 473 | 600 | 708 | 775 | |||||||||||

| PN64 | 206 | 210 | 251 | 286 | 311 | 337 | 394 | 508 | 650 | 752 | 819 | |||||||||||

| H1(PN16) | 52.5 | 57.5 | 72.5 | 80 | 90 | 97.5 | 107.5 | 140 | 167.5 | 202.5 | 230 | |||||||||||

| With PSL | H | Common type | 738 | 750 | 765 | 767 | 845 | 857 | 875 | 1025 | 1045 | 1252 | 1545 | |||||||||

| Fin type | 888 | 900 | 935 | 937 | 1025 | 1037 | 1055 | 1255 | 1280 | 1532 | 1825 | |||||||||||

| D | 176 | 225 | ||||||||||||||||||||

| KG(PN16) | 14 | 16 | 25 | 28 | 40 | 50 | 65 | 150 | 250 | 380 | 550 | |||||||||||

| With 361l | H | Common type | 500 | 512 | 652 | 660 | 770 | 780 | 790 | 1080 | 1125 | 1250 | 1265 | |||||||||

| Fin type | 650 | 662 | 822 | 822 | 950 | 960 | 970 | 1310 | 1360 | 1530 | 1545 | |||||||||||

| D | 225 | 310 | ||||||||||||||||||||

| KG(PN16) | 20 | 22 | 30 | 35 | 50 | 60 | 75 | 180 | 280 | 420 | 580 | |||||||||||

Note: height, weight of the reference value, as the executing agency and.

Electronic type electric seat regulating valve overview

ZDLN type electronic seat regulating valve, an adjusting instrument input (4-20mA DC, 0-10mA DC or 1-5V DC) control operation can be a control signal and power supply, automatic control on the process of fluid pipeline. Process parameters are widely used in precise control of gas, liquid medium, steam and other parameters such as pressure, flow, temperature, liquid level, maintained at a given value, is common in accordance with the IEC standard valve products. Two seat valve has unbalanced force is small, allowing a large pressure difference, flow capacity, is suitable for leakage is not strict, pressure clean medium large occasions, widely used in electric power, metallurgy, chemical industry, petroleum, environmental protection, light industry, equipment industry.

The main technical parameters of electric valve seat

| DN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | ||||||

| Seat diameter mm | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | ||||||

| Rated number Kv | 10 | 16 | 25 | 40 | 63 | 100 | 160 | 250 | 400 | 630 | 1000 | 1600 | 2000 | 2700 | ||||||

| Nominal pressure (MPa) | 1.6,2.5,4.0,6.4,10 | |||||||||||||||||||

| Trip(mm) | 16 | 25 | 40 | 60 | 100 | 130 | ||||||||||||||

| Flow characteristics | Linear, equal percentage, quick opening | |||||||||||||||||||

| Working temperature ℃ | -40~+230 ℃ (Chang Wenxing), fin type +230~+450 ℃ (medium temperature) special orders | |||||||||||||||||||

| Flange size | According to JB/79.1 (2) -94, HG20592-97, GB, ANSI, JIS, DIN and other standards | |||||||||||||||||||

| Body material | WCB, 304, 316, WC6, WC9, nickel, titanium, Hastelloy, Monel etc. | |||||||||||||||||||

| Valve material | 304, 316, 420, nickel, titanium, Hastelloy, Monel etc. | |||||||||||||||||||

| The valve type | Through two seater casting ball valve | |||||||||||||||||||

| The valve cover type | Ordinary type (room temperature), hot chip (temperature) | |||||||||||||||||||

| The electric actuator | PSL-202 | PSL-204 | PSL-208 | PSL-312 | PSL320 | PSL325 | ||||||||||||||

| 361L | 361LSA-20 361LSA-20 | 361LSB-30 361LXB-30 | 361LSB-50 361LXB-50 | 361LSC-65 361XC-65 | 361LSC-99 361LXC-99 | 361LSC-160 361LXC-160 | ||||||||||||||

Technical parameters of electric actuator

| Model | output power N | Speed mm/s | Technical parameters | ||||

| PSL | 361L | PSL | 361L | PSL | 361L | PSL | 361L |

| 201 | 361LSA-08 361LXA-08 | 1000 | 800 800 | 0.25 | 4.2 4.2 | ||

| 202 | 361LSA-20 361LXA-20 | 2000 | 2000 2000 | 0.50 | 2.1 2.1 | Power supply: AC220V 50HZ Input signal: DC4-20mA DC1-5V (shielding line signal line): DC4~20mA output signal Protection grade: IP67 With the handwheel | Power supply: AC220V 50Hz Input signal: DC4-20mA DC1-5V (shielding line signal line) Output: DC4~20mA Protection grade: IP65 Flameproof mark: Exd ll BT4 With handle |

| 204 | 361LSB-30 361LXB-30 | 4500 | 3000 3000 | 0.50 | 3.5 3.5 | ||

| 208 | 361LSB-50 361LXB-50 | 8000 | 5000 5000 | 1.00 | 1.7 1.7 | ||

| 312 | 361130-65 | 12000 | 6500 | 0.60 | 2.8 | ||

| 320 | 361LSC-99 | 20000 | 10000 | 1.0 | 2.0 | ||

Note: other optional electric actuator Siemens: Yangzhou, UK.

| DN | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | |||||||||||

| Seat diameter (mm) | 10 | 12 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | ||||||

| Actuator | To allow pressure △P(MPa) | |||||||||||||||||||

| With PSL | PSL202 | 6.4 | 6.4 | 6.4 | 4.90 | 3.14 | 1.92 | 1.23 | 0.78 | |||||||||||

| PSL204 | 4.31 | 2.76 | 1.76 | 1.04 | 0.69 | 0.44 | ||||||||||||||

| PSL208 | 1.86 | 1.23 | 0.78 | 0.50 | 0.35 | 0.20 | ||||||||||||||

| PSL320 | 1.26 | 0.87 | 0.49 | |||||||||||||||||

| With 361L | 361LSA-20 | 6.4 | 6.4 | 6.4 | 4.90 | 3.14 | 1.92 | 1.23 | 0.78 | |||||||||||

| 3611SB-50 | 4.79 | 3.06 | 1.96 | 1.16 | 0.76 | 0.49 | ||||||||||||||

| 3611SC-65 | 1.51 | 0.99 | 0.64 | 0.41 | 0.28 | |||||||||||||||

| 3611SC-99 | 0.63 | 0.44 | 0.25 | |||||||||||||||||

1, the electric single seat valve to allow pressure

Note: the actual configuration should be determined according to the process parameters. If the maximum working pressure exceeds the range on the table, please contact with me.

Company :mm

| All diameter. | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | |||||||||||

| L | PN16 | 187 | 184 | 222 | 254 | 276 | 298 | 352 | 451 | 600 | 673 | 737 | ||||||||||

| PN40 | 194 | 197 | 235 | 267 | 292 | 317 | 368 | 473 | 600 | 708 | 775 | |||||||||||

| PN64 | 206 | 210 | 251 | 286 | 311 | 337 | 394 | 508 | 650 | 752 | 819 | |||||||||||

| H1(PN16) | 52.5 | 57.5 | 72.5 | 80 | 90 | 97.5 | 107.5 | 140 | 167.5 | 202.5 | 230 | |||||||||||

| With PSL | H | Common type | 738 | 750 | 765 | 767 | 845 | 857 | 875 | 1025 | 1045 | 1252 | 1545 | |||||||||

| Fin type | 888 | 900 | 935 | 937 | 1025 | 1037 | 1055 | 1255 | 1280 | 1532 | 1825 | |||||||||||

| D | 176 | 225 | ||||||||||||||||||||

| KG(PN16) | 14 | 16 | 25 | 28 | 40 | 50 | 65 | 150 | 250 | 380 | 550 | |||||||||||

| With 361L | H | Common type | 500 | 512 | 652 | 660 | 770 | 780 | 790 | 1080 | 1125 | 1250 | 1265 | |||||||||

| Fin type | 650 | 662 | 822 | 822 | 950 | 960 | 970 | 1310 | 1360 | 1530 | 1545 | |||||||||||

| D | 225 | 310 | ||||||||||||||||||||

| KG(PN16) | 20 | 22 | 30 | 35 | 50 | 60 | 75 | 180 | 280 | 420 | 580 | |||||||||||

Ordering instructions

When ordering, please fill in "specification" or indicate the following contents:

One, if the order has not selected models, please provide the parameters are used to send us your

1, nominal diameter, the rated flow coefficient Kv

2, the fluid properties (including the nominal pressure, temperature, viscosity and pH)

3, the valve action form (electro - closed or electric - Open)

4, flow characteristics

5, in front of the valve, the valve pressure

6, valve body, valve core material

7, the input signal

8, with the attachment, the attachment type, so that we can correct for your selection.

Two, special requirements

1, special inspection

2, complete degreasing, water treatment;

3, no copper processing;

4, special interface, piping;

5, the use of vacuum conditions;

6, specify the color of the coating

7, special medium (oxygen, chlorine, hydrogen);

8, the use of stainless steel connections;

Three, if the unit has been selected from the design of our products, please click models directly to our sales department to order, please try to provide design drawings and detailed parameters, from our experts to your review gatekeeper

Four, the occasion is very important when using more complex or pipeline.

.jpg)