Steel Anchor netting wire mesh

| Min. Order: | 1 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 50,000 square meters per year |

| Place of Origin: | Sichuan |

Company Profile

| Location: | Chengdu, Sichuan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | R25N - T76S |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Others |

| Type: | Others |

| Material: | Others |

| Brand Name: | ONTON |

| Mesh Size: | 2m to 4m horizontal and vertical spacing |

| Usage: | Soil or rock nails, Slope stabilization, Temporary excavation shoring |

| Test Report: | SGS |

| Tools: | self-drilling rock anchor |

| Material: | Steel |

| Certificates: | CE, ISO |

| Production Capacity: | 50,000 square meters per year |

| Packing: | Cartons |

| Delivery Date: | In 10 days |

Product Description

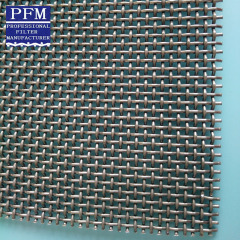

Steel Anchor netting wire mesh

Steel Anchor netting wire mesh in Soil Nail shoring Application

The Soil Nail shoring system consists of driven steel bars with a composite geotextile fabric and wire mesh face, improving installation time by 50% over conventional shoring methods.

The mesh is made of high-tensile steel wire with an ultimate tensile strength of 2000 N/mm2.

APPLICATIONS

Adapted to the local soil and rock static requirements, the steel anchor netting wire mesh can be anchored in accordance with our dimensioning concept with commercial soil or rock nails.

Temporary excavation shoring

Slope stabilization

Soil or Rock Nails

Soil Nail Net Wire Mesh

Steel Anchor netting wire mesh Features

Anti-corrosion

Easy to install

Zero-maintance

INSTALLATION

Normal Steel Solid Bars (soil nails):

Excavate 5 feet

Place geocomposite wall face

Drive steel bars

Proof test driven nails

Repeat process to bottom of excavation

Steel Hollow Bars (self drilling grout injection anchors):

Drilling and grouting

Place geocomposite wall face

Proof test driven nails

Repeat process to bottom of excavation

The steel anchor net wire mesh can be installed combined with soil or rock nails (hollow bar anchors or solid anchor rods), improving over 50% time to finish the shoring or slope stablization projects.

Project case

Nuozhadu Power Plant - Slope Protection

More projects cases on self drilling hollow bar anchor and rock bolts, please visit the Reference pages.

And the key features presentation of anchor bar strength, ductility, steel grades.

.jpg)