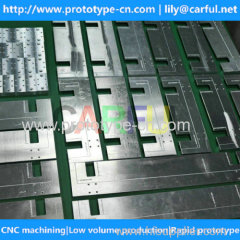

cnc machining parts factory

| Place of Origin: | Guangdong |

|---|

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Material: | Material |

|---|---|

| Milling way: | CNC |

| Surface: | Anodizing |

Product Description

cnc machining parts factory,cnc machining parts manufacturing

Established in 1999, HT Group is a family owned

company specializing in Mold making and one stop die casting alloy part

& injection molding

Company history

1999: Company established, with 300㎡ area

2003: Occupied 8000㎡ area

2010: Die Casting Factory established, occupied 8600㎡ totally.

2012: Occupied 22000 ㎡ area

2013: Annual Output: USD60 million (Today we own 500 employees)

Products & Services:

Mold / Tool Designing

Mold/Tool Building

Molded Plastic Parts

Die Casting Alloy Parts

Printing

Silk Screening

Packaging

Industries Served: Automobile, Electrical, Electronics, Industrial, Medical

Security, furniture, OE, Packaging, etc.

Our Capability

Mold / Tooling: 600~700 sets annually

Molded Plastic Parts: USD 12 million annually

Die Casting Alloy Parts: USD 24 million annuall

Designing is critical for mold quality. Therefore, we pay special attention to the mold designing such as the structure, the selection of mold steel, gate position, cooling channels and moving mechanisms to ensure the possible highest quality at lowest cost.

Mold design steps:

1, Part analysing;

2, Suggestions about plastic parts

3, 2D mold design / part modification

4, 2D mold drawing for customer reviewing

5, 2D modification for customer release

6, Complete 3d mold design

7, Component 2d drawing

Software that we used:

PROE

AUTOCAD

MOLDFLOW

SOLIDWIRK

UG

We can provide Moldflow Analysis report including analysis of wrap, cooling, fill time, temperature, air traps, welding lines, shear rate, shrinkage, etc.