aluminum alloy casting Factory

| Place of Origin: | Guangdong |

|---|

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Part material: | AZ91D |

|---|---|

| Part weigh: | 1.8 kg |

| Surface: | spray powder |

| Produce machine: | 650T |

Product Description

China aluminum alloy casting Factory

Part material: AZ91D

Part weigh: 1.8 kg

Surface: spray powder

Produce machine: 650T

Our die casting factory was founded in April, 2010, occupies 8600 ㎡ with 90 employees.

We own hot chamber machine 138T, Cold chamber machines 180T, 280T 400T, 650T,800T

Die Casting alloy part type:

Magnesium die casting alloy parts

Aluminum die casting alloy parts

Zinc die casting alloy parts

Raw alloy materials as follows:

Mg: AZ91D, AM50A, AM60B

Al: ADC10, ADC12, A380

Zn: Zamak-3, Zamak-5, Zamak-7

Secondary machining:

CNC milling CNC lathe

Drilling Tapping

Multi-head drilling

Multi-head tapping

Surface treatment for alloy parts:

Deburring Brass Plating

Chrome / Nickel Plating Anodizing

Painting Powder Paint

Shot blasting Polish

Please

feel free to contact us for any questions, whether it is about die

casting mold or alloy parts. We are able to provide you professional

solution.

If you have new project on hand, please feel free to send us inquiry.

We will send quotation to you in 24 hours.

Hot chamber machine 138T,

Cold chamber machines 180T, 300T 400T, 650T,800T

Secondary machines include: CNC, CNC lathe, Drilling, Tapping

Multi-head drilling, Multi-head tapping, sand spray machine, etc

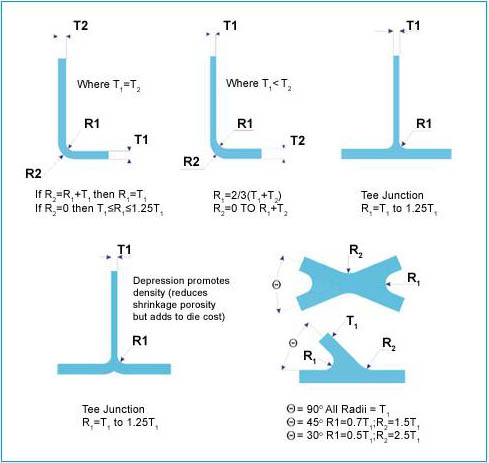

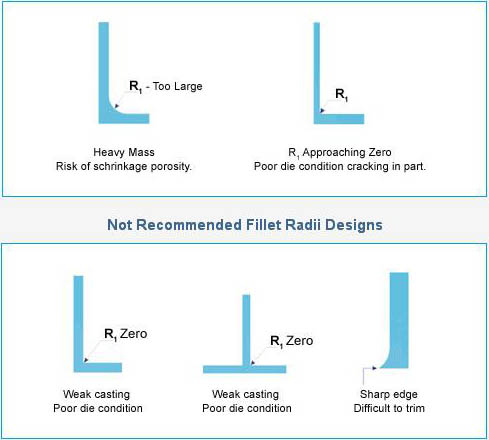

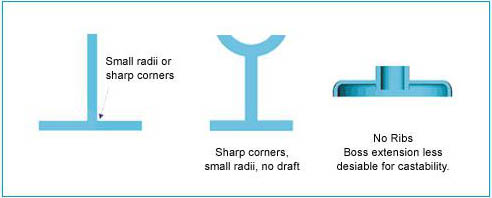

Part radius are extremely important in die castings and often neglected by component designers.

To avoid high stress concentrations in the component and the die casting tool, fillet radii of the appropriate size must be

used in all internal and external component edges.

The exception to this rule is where the feature lands on the parting line of the tool.

Another important aspect concerning fillet radii is that they assist in filling the part die.

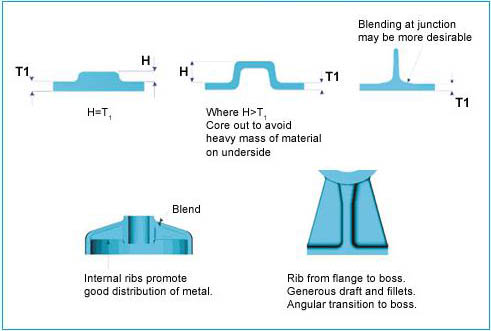

Die casting ribs are used to:

* Increase the stiffness of a component.

* Add strength to a component.

* Assist in the production of a sound casting.

If

the component in question is a structural part, careful consideration

must be given to the design of casting ribs, especially in areas of high

stress. Properly proportioned fillet radii must be used to avoid high

stress concentrations at the junction of the rib and the main component.

This can also assist in producing a sound casting by providing a means

of distributing the metal. Current die casting technology permits

thinner and deeper ribs than were previously possible. However the ratio

of width to depth does have a significant bearing on the design of the

tool and the processes used to manufacture it.

Headquarters: ZhenAn east road, ChangAn, DongGuan city, GuangDong province, China

HT Die casting factory: Xintang road-1, Datang, DalingShan, DongGuan city, GuangDong province, China

HT-Mold making branch: Maozouhe Industrial, Shapuwei, SongGuang, ShenZhen city, GuangDong province, China

Marketing Dept: Diwang 2106, ChangQing road, Changan Town, DongGuan 523845, China