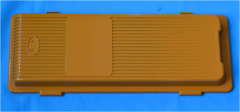

Magnesium alloy die casting

| Place of Origin: | Guangdong |

|---|

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Material: | AZ91D |

|---|---|

| Cav number: | 1X4 cavities |

| Part weigh: | 196g /each |

| Molding machine: | 800T |

Product Description

Magnesium alloy die casting

Request: take off burrs-2nd milling -oxide coating – powder coating

Our die casting factory was founded in April, 2010, occupies 8600 ㎡ with 90 employees.

We own hot chamber machine 138T, Cold chamber machines 180T, 280T 400T, 650T,800T

Die Casting alloy part type:

Magnesium die casting alloy parts

Aluminum die casting alloy parts

Zinc die casting alloy parts

Raw alloy materials as follows:

Mg: AZ91D, AM50A, AM60B

Al: ADC10, ADC12, A380

Zn: Zamak-3, Zamak-5, Zamak-7

Secondary machining:

CNC milling CNC lathe

Drilling Tapping

Multi-head drilling

Multi-head tapping

Surface treatment for alloy parts:

Deburring Brass Plating

Chrome / Nickel Plating Anodizing

Painting Powder Paint

Shot blasting Polish

Please

feel free to contact us for any questions, whether it is about die casting mold or alloy parts. We are able to provide you professional

solution.

If you have new project on hand, please feel free to send us inquiry.

We will send quotation to you in 24 hours.

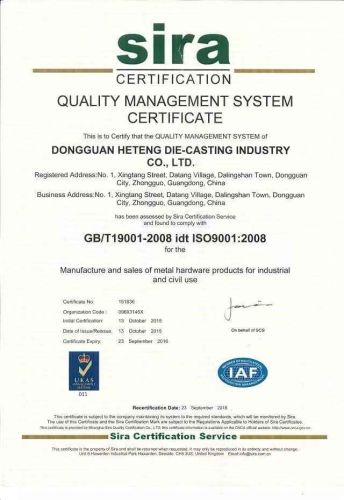

Quality

is the life of enterprise, the foundation stone of development. We have

strong sense of quality. Not only do we have rich experiences in mold

making and injection molding, but also we own completed inspection and

control program for high-end die casting products.

Quality control process for die casting products,

1. Analyzing and inspection of raw materials,

2. Inspection and evaluation of mold / tool before production,

3.Inspection of molded part, including flatness, dimension, compactness, etc.

4. Strictly control the dimension on every step during the secondary machining,

5.Dimension inspection at Random. Prepare CPK report,

6. Product surface inspection,

7. Pre-pack inspection

Headquarters: ZhenAn east road, ChangAn, DongGuan city, GuangDong province, China

HT Die casting factory: Xintang road-1, Datang, DalingShan, DongGuan city, GuangDong province, China

HT-Mold making branch: Maozouhe Industrial, Shapuwei, SongGuang, ShenZhen city, GuangDong province, China

Marketing Dept: Diwang 2106, ChangQing road, Changan Town, DongGuan 523845, China

E-mail: Info@htmould.com