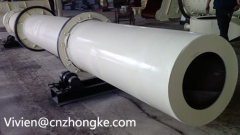

Coal Ash Dryer Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 sets/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Stone Crusher, Sand Maker, Powder Making Machine, Etc |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Application: | Ore |

| Type: | Others |

| Brand Name: | FTM |

| Production Capacity: | 100 sets/month |

| Packing: | standard container |

| Delivery Date: | 25 days |

Product Description

Introduction

Wet coal ash is sent into the hopper of coal ash dryer machine by belt conveyor or bucket elevator, and then sent into feed end through feeding pipe of feeder hopper. The dryer cylinder of the coal ash drying machine is a rotating cylinder with slight incline to the horizontal line. The materials are sent from the higher end and the heat-carrying agents are sent from the lower end to be countercurrent contact with the materials. Some heat-carrying agents and materials flow altogether into the end of the barrel with the gravity effect as the rotation of the cylinder. In the process of moving forwardness in the barrel, the wet materials are directly or indirectly gained the heat of the heat-carrying agent and be dried in China coal ash dryer or coal ash drying equipment, then finished products will be discharged through belt conveyor or screw conveyor.

Features of Coal Ash Dryer Machine

1.Its equipment investment is 1/6 of product introduced from abroad.

2.The final moisture content of materials is guaranteed under 0.5%. The pulverized fuel ash dryer is your first choice in coal ash and slag production line.

3.The self heat preservation efficiency of cylinder can reach 80% (the traditional single drum dryer is only 35%), which can improve thermal efficiency by 45%.

4.Its fuel can adopt coal, oil and gas. The fly ash dryer can dry powder, granular or lump shaped materials under 20mm.

5.Save covering area by about 50%, construction investment by 50% or so and electricity cost by 60%, compared with single drum dryer.

6.The alloy steel plate it uses is 4 times stronger in wear resistance than the common steel.