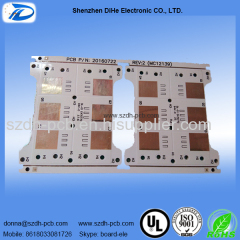

2 Layer COB Metal Core PCB

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 20000m2/month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | MCPCB, FR4 PCB, Ceramic PCB |

Product Detail

| Model No.: | BAD12207 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| structure: | COB |

| board thickness: | 1.0mm Aluminum |

| copper thickness: | 1 OZ |

| Thermal conductivity: | 137 W/m-K |

| base material: | •Silver plating mirror surface aluminum |

| BT material (high Tg): | 0.10mm |

| solder mask: | White |

| Surface: | ENIG |

| Production Capacity: | 20000m2/month |

| Packing: | vaccum |

| Delivery Date: | 3-7 days |

Product Description

COB MCPCB General InformationCOB MCPCB, known as "Chip-On-Board" Metal Core PCB, is a type of MCPCB used in thermoelectric separation application. By using COB MCPCB, the micro-chip (also known as "die") directly touch the metal core where the heat dissipate, and electrically interconnect the trace of circuit board (wire-bonding) so that power supply can be provided. In normal MCPCB, there's a dielectric layer between trace copper and metal core, and the thermal conductivity is limited by that dielectric layers, so value can only be 1~3 W/m.K. But using COB MCPCB, there's no such dielectric layer because chip (die) direct touch the metal core, so thermal conductivity value of COB MCPCB will be almost the same one of metal core material itself. The normal material of metal core is aluminum, so thermal conduviity of COB MCPCB is more than 200W/m.K. COB process consists of three main categories to perform when manufacturing the Chip-on-Board: 1st: 'die mount or die attach'; By using wire bonding & epoxy packaging then directly embedded on MCPCB, this practice can extend the lifespan of LED and unified light emission. According to process and material, COB MCPCB applications can be categorized into two types: Mirror Aluminum and silver or gold platting aluminum, or silver plating mirror aluminum PCB. | |

Structure of COB MCPCB | |

| Advantage of utilizing COB MCPCB | |

| |

| Application of COB MCPCB | |

| |

| Please contact us for more information about the COB MCPCB. | |