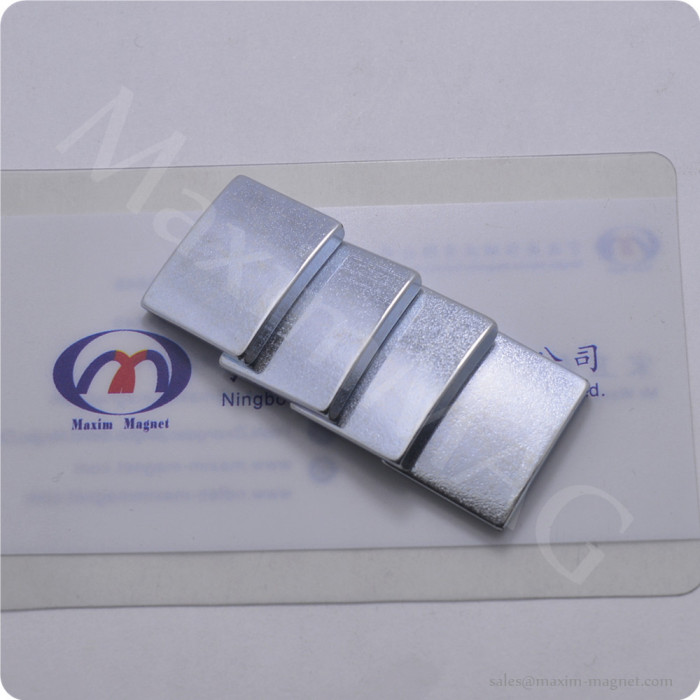

High strength Neodymium arc segment magnets

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 1million per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | AM-MaximMAG |

|---|---|

| Means of Transport: | Ocean, Air, Land, courier express |

| Shape: | Arc |

| Application: | Motor Magnet |

| Type: | Permanent |

| Composite: | NdFeB Magnet |

| Brand Name: | MaximMag |

| Coating: | 3 layer NiCuNi |

| item: | Neodymium arc segment magnets |

| magnetization: | half N/S, and half S/N |

| brand: | MaximMAG |

| Production Capacity: | 1million per month |

| Packing: | neutral, 330x260x150mm carbonboard carton |

| Delivery Date: | 2-4 weeks |

Product Description

Material: High strength Neodymium arc segment magnets;

Specification: customized;

Grade: N35-33AH;

Coating: 3 Layer Ni-Cu-Epoxy etc. ;

Magnetization: diametrically magnetization;

Application: wheel hub motors, permanent magnet synchronous motors, starter motor, innovative light motor, Industrial application.

neodymium curved magnets

Place of Origin | Ningbo, China (Mainland) |

| Brand Name | MaximMAG |

| Type | Rare earth Neodymium magnets |

| Shape | disc, block, arc, ring, cylinder, tube, ball, cube, etc. |

| Product name | Neodymium Magnets, NdFeB, NIB, Rare earth permanent magnets |

| Material | Neodymium-iron-boron |

| Size | from 1mm to 240mm, customized. |

| Grades | N35-N52, 35M-50M, 33H-48H, 33SH-45SH, 30UH-40UH, 28EH-38AH, 30AH-35AH |

| Max theoretical Working temperature | 80 - 250 degrees |

| Coatings | NiCuNi, Zn, Epoxy, Cr, etc. |

| Delivery time | 10-21 days regularly |

| Packaging | regularly 8 small white boxes into a carton of 35*26*15cm |

| Applications | Magnetic tools, EPS motors, micro motors, stepper motors, servo motors, BLDC Motors, wheel-hub motors, texture motors, vibration motors, wind turbines/generators, permanent magnet synchronous motors, elevator motors, magnetic switches, NMR, magnetic separators, magnetic filters, sensers, automobile startor motors, loudspeakers, magnetic drives etc. |

Your detailed request information will facilitate our quick and acurate offerings:

1. Magnet size, for arc/segment magnets we require a drawing to better understanding the design;

2. Magnet grade. We make standard magnetic grades as well as special magnetic property to customers' requirements;

3. Coating. Regular coatings can be find in MaximMAG certainly, such as Ni-Cu-Ni, Zn, Epoxy, Pasivate, NiCuNi+Cr etc;

4. Magnetization. Usually customers require magnetized through thickness;

5. Quantity.

At last, your information on how you use magnets in your applications will always be appreciated, and we're giving rebates if feedback photos how the magnets used.