Small Neodymium square block magnets

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T, Money Gram |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | BM-MaximMAG |

|---|---|

| Means of Transport: | Ocean, Air, Land, courier express |

| Shape: | Block |

| Type: | Permanent |

| Application: | Industrial Magnet |

| Composite: | NdFeB Magnet |

| Brand Name: | MaximMag |

| Coating: | Nickel-Copper-Nickel |

| Density: | 7.5g/mm³ |

| Packing: | neutral, 330x260x150mm carbonboard carton |

| Delivery Date: | 2-4 weeks |

Product Description

Neodymium square/block magnets

1)Shape: square/block/rectangular etc

2)Grade: from 11.7-14.8kGs;

3)Certificate:ISO9001:2008;

4)Sintered Neodymium magnets;

5)Not only standard magnets but also magnets of low weight loss and low temperature coefficient;

Specification of Neodymium Magnets:

Chemical composition: Nd2Fe14B.

Neodymium magnets are hard, brittle and easily being oxidized.

Thermal stability

-0.09 ~ -0.13% of Br/°C (when inquiring let us know the temperature range).

Satisfactory magnetic properties

Br:

11.7-14.8 kGs, Hcj: 10-35 kOe, BHmax: 33-53 MGOe. MaximMAG guarantees

magnets with standard magnetic properties as to clients' expectation.

Advanced Technology

Thanks to strip casting and HDDR technology, we avail of this technology to make high quality strips for all high performed magnets.

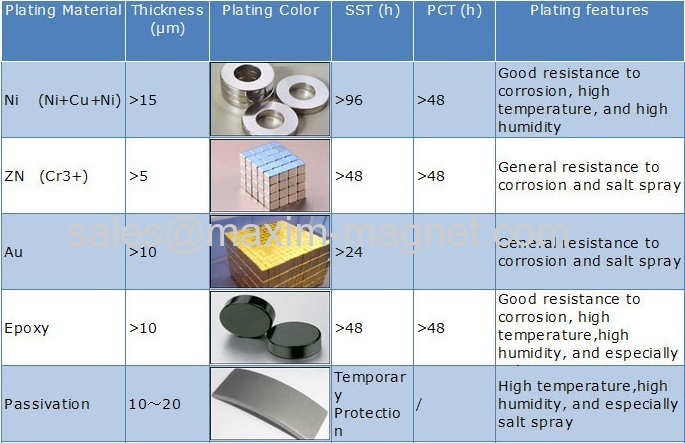

Effective surface treatment management

Because of high polluted industry, surface treatment is outsourced. With good management and professional konwledges we offer satisfactory magnets with good coatings.

All our magnets are customized made, so your kindly email us following information will be highly appreciated.

1. Dimensions, drawing is preferrable.

2. Magnet grade you're looking for;

3. Coating of the magnets: NiCuNi, Epoxy, Zinc, Passivation etc.

4. Magnetized direction, usually through the smallest dimension;

5. Quantity;

6. Constant working temperature;

7. Your information on how you use magnets in your applications will always be appreciated.

small block magnets