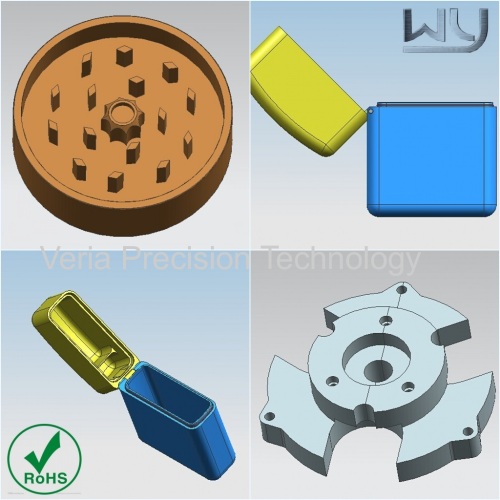

CNC machined part cnc machining copper parts precision stainless steel cnc machining parts cnc part machining

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 10000 per mouth |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

| Main Products: | Cnc Machined Aluminum Stainless Steel Car Metal Copper Part, Cnc Machined Part, Cnc Machine Part, Cnc Machining Part |

Product Detail

| Model No.: | WLY-05-008 |

|---|---|

| Means of Transport: | Ocean, Air |

| Brand Name: | WY |

| Materials: | Copper, aluminum, stainless steel, aluminum alloy, titanium alloy, steel, plastic |

| Process: | CNC milling and turning, drilling, grinding, bending, stamping, tapping |

| Tolerance: | 0.005mm~0.1mm |

| Surface Roughness: | Ra1.6-3.2 |

| DRW format: | PDF/DWG/IGS/STP/ etc |

| Equipment: | CNC machining center, CNC turning, General milling machines |

| Capacity: | 10, 000pieces per month |

| Production Capacity: | 10000 per mouth |

| Packing: | carton |

| Delivery Date: | 7-15days |

Product Description

Name: China Precision CNC Machined Parts, Custom CNC Machining Service,cnc machining milling parts,cnc plastic machining parts, precision cnc machining stainless steel parts,aluminum parts cnc machining parts,cnc metal machining parts,cnc turning machining parts,cnc copper turning machining parts

Materials: Copper, aluminum, stainless steel, aluminum alloy, titanium alloy, steel, plastic

Process: CNC milling and turning, drilling, grinding, bending, stamping, tapping

Tolerance: 0.005mm~0.1mm

Surface Roughness: Ra1.6-3.2

DRW format: PDF/DWG/IGS/STP/ etc

Equipment: CNC machining center, CNC turning, General milling machines.

Capacity: 10, 000pieces per month

Machining Scope:

1). Equipment/Machinery parts

2). Medical & Technological parts

3). The Automotive/motorcycle parts

4). The telecommunication parts

5). The power tool parts

6). Bicycle parts

7). The agricultural parts

Company Advantage

1) ODM&OEM with ONE-STOP Solution Service

2) Small quantity with mixed items is also available

3) High Precision, New Technology, Competitive Price

4) Advanced laser cutting machines available.

5) All kinds of facility, CNC machining, turning, milling, tapping, drilling, polishing, punching, etc...

6) Competitive Prices, Excellent Service, and Good Lead Time.

7)Advanced technology and R & D personnel

HOW CNC MACHINING WORKS

The CNC Machining process can be broken down into three steps:

Step 1: 3D CAD files are analyzed to determine the fixturing required and the most cost effective method to machine the part.

Step 2: Machine code for fixtures and the manufacturing of the part is generated using Master cam software.

Step 3: The product is then manufactured to the customer's dimensional and surface finish specifications using high speed, precision CNC machining equipment and tools.

ADVANTAGES OF CNC MACHINING

Next Line offers CNC machine services for clients who require producing precision metal parts. CNC machining is one of the fastest way to build quality market-testing prototypes and production parts. Read on to learn more about the benefits of our CNC machine services.

Subtractive technologies are often thought of as old school, but Next Line is bringing CNC Machining into the next generation. Our leading-edge machines use the latest technology to turn your 3D CAD file into a high-quality, precision production part in as fast as 24 hours.

Perfect for low-volume to production quantities

Smooth finishes on a solid metal or plastic parts, produced exactly to design specifications

Offers high-precision tolerances and easily reproducible processes

Lead times of less than a week