Automatic PU Slippers shoes sole Rotary making production line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 20 sets/per month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Foshan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | PU Foam Machine, Shoe Making Machine, PU Sole Machine, Ear Plug Machine, Sponge Making Machine |

Product Detail

| Model No.: | LZ-XC24 |

|---|---|

| Means of Transport: | Ocean |

| Raw Material: | Others |

| Power: | Others |

| Machine Type: | Others |

| Automation: | Automatic |

| Extra Services: | Others |

| Material / Metal Processed: | Others |

| Certification: | ISO 9001:2000 |

| Brand Name: | LUZHOU |

| Power supply: | All power of the machine 12KW,4*380V/50HZ |

| The type of applicable foam: | Sole,insole, walking shoe, ect. |

| Flux of inject: | 30g-100g/S (Attention:the flux could be configured) |

| The press of infect: | 0.1MPA-3.99MPA |

| The mix proportion: | 100-65;100-110 |

| Time of injecting: | 0.01-9.99/S( precision 0.01S) |

| Precision of injection: | 0.1/100 |

| Process of injecting: | Manual inject by PLC programmed |

| Pneumatic pressure: | 0.6-0.8MPa |

| Pouring nozzle: | With collision impact needle |

| Production Capacity: | 20 sets/per month |

| Packing: | plastic paper |

| Delivery Date: | 30 days after received the depoist |

Product Description

Specifications:

1.PU Slippers shoe sole making machine with Rotary table production line

2.20 years manufacturing experience

3.OEM/ODM welcome

Equipment model: LZ-XC60

Product Purpose:

This machine is used for the formation of various twin-color and single-color polyurethane soles for making various high and medium class Slippers, leather shoes, casual shoes, safety shoes, travel shoes, bicycle seats and toys

Product Characteristics:

Imported components are used for the metering pump and electrical components, greatly enhancing equipment running reliability and service life.

New generation programmable controllers are provided with more comprehensive and practical functions, making the machine more convenient to operate; a needle valve type never worn injector is used to further ensure product quality.

The moulds using pneumatic coling, to reduce the costs and labor, also reduce the waste caused by the operation.

The mold using the circulating water heating method, it can save 3/2 energy as the traditional way, in this way, the temperature of the mold can control within ±2 °C .

Sample Pictures:

About Us:

Foshan Luzhou PU Machinery Co.,Ltd, is one of the best PU machinery fabricator which was founded in 2013. It is located in the Eastern of Nanhai, Foshan and near to Guangzhou.

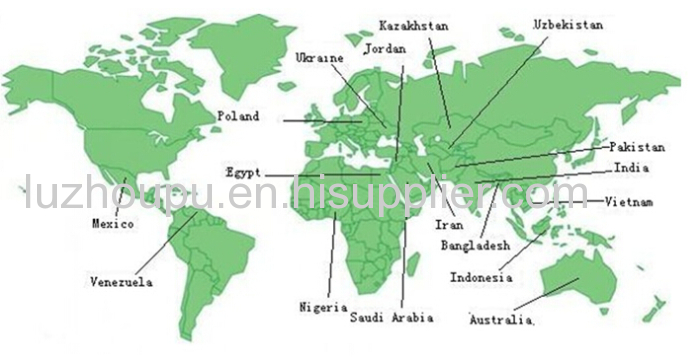

As professional pu machinery factory, Luzhou has the most excellent work team, they have specialized in this industry for more than 20 years, who is the top expert in PU industry. Luzhou always insist on the ideas "Innovation is the best power which can make the enterprise move on". Luzhou has developed its own new items with strong enthusiasm on the basis of traditional PU equipments. Its products are sold well all over the world.

Luzhou produce the best brand with its professional qualification and is highly appraised by its superior quality with highly-efficient service. In the future, Luzhou will expand its business with stronger business management and service system.

Selling Well All Over The World:

If any questions please contact us!

Contact:Yuki Tang

Skype:yukitang2014;

Wechat:yukitang988;