Shoe Sole Automatic Production Equipment

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 20 set/per month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Foshan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | PU Foam Machine, Shoe Making Machine, PU Sole Machine, Ear Plug Machine, Sponge Making Machine |

Product Detail

| Model No.: | LZ-XC24 |

|---|---|

| Means of Transport: | Ocean |

| Flux of inject: | 30g/s-100g/s |

| press of infect: | 0.1MPA-3.99MPA |

| mix proportion: | 100-60;100-110 |

| Time of injecting: | 0.01-9.99/s |

| Precision of injection: | 0.1/100 |

| Pneumatic pressure: | 0.6-0.8MPA |

| Production Capacity: | 20 set/per month |

| Packing: | wooden |

| Delivery Date: | 30 days after received the deposit |

Product Description

Specifications:

1. PU Shoe Sole Production Machine.

2. Best quality and best price.

3. CE approval.

4. Best after sales service.

Product Purpose:

This machine is used for the formation of various twin-color and single-color polyurethane soles for making various high and medium class leather shoes, casual shoes, safety shoes, travel shoes, bicycle seats and toys.

Product Characteristics:

1. Imported components are used for the metering pump and electrical components, greatly enhancing equipment running reliability and service life.

2. New generation programmable controllers are provided with more comprehensive and practical functions, making the machine more convenient to operate; A needle valve type never worn injector is used to further ensure product quality.

3. The moulds using pneumatic coling, to reduce the costs and labor, also reduce the waste caused by the operation.

4. The mold using the circulating water heating method, it can save 3/2 energy as the traditional way, in this way, the temperature of the mold can control within plusmn.

Sample Photo:

Our Service:

1.Free to visit, introduce, do Selection Guide;

2. Free to visit home clients to know in-service condition of machine;

3. Test and adapt whole setting data here as according clients'demands;

4. Send experienced engineers to guide installation, operation, debugging and maintain;

5. Rich supporting suppliers of molds, chemical and others for reference.

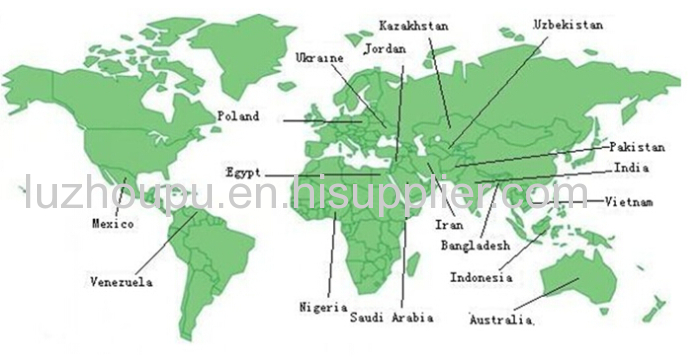

Selling Well All Over The World: