SZL Assembly Water Tube Boiler

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60sets/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Agent |

| Main Products: | Gas Fired Boiler |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Structure: | Fire Tube |

| Output: | Steam |

| Type: | Natural Circulation |

| Fuel: | Coal-fired |

| Style: | Horizontal |

| Pressure: | Low Pressure |

| Usage: | Industrial |

| Brand Name: | ZG |

| Production Capacity: | 60sets/month |

| Packing: | standard |

| Delivery Date: | 60 |

Product Description

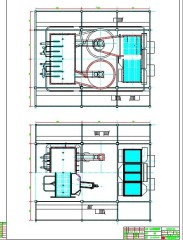

SZL type assembly water tube boiler adopts double drum longitudinal decoration, and combustion mode was chain grate. With the rate of 4 ~ 20 t/h, it uses the higher inlet to meet the needs of the biomass fuel.

Application:

Combustion of biomass fuel molding can be pure coal or mixed coal and biomass fuel molding to provide heat or power generation

Product structure:

The boiler consists of two large chain grate biomass boiler out of factory , up major possession including boiler body , upper steel frame and furnace wall ,lower bulk including coal bucket ,chain grate ,lower furnace wall, and internal ventilation tube.

Advantages:

1. Combustion and both sides of the furnace chamber adopt membrane water-cooling wall structure. With this kind of structure, the boiler has a high heat transmission coefficient, low heat loss, good airtightness, no distortion for furnace wall and no ash leakage.

2. Furnace front and rear water wall tube extend down to the upper portion of the grate and form the front and back arch, which extends the span of arch.

3. Inverted "α" arch furnace technology makes the front arch high and short, rear arch low and long. This structure increases the burning time of the flue gas in the furnace so as to improve the combustion efficiency. Besides, the streamline shape of back arch can throw the left carbon grains from the back furnace grate into the front so that the coal is easier to get ignited. Finally, many types of coal can be applied in the boiler.