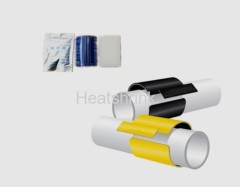

3PE Heat Shrinkable Wraparound Sle eves - WSS

| Place of Origin: | Jiangsu |

|---|

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | Heat Shrinkable Sleeves, Anti-corrosion Tape, Heat Shrink Tube |

Product Detail

| Brand Name: | Heatshrink |

|---|

Product Description

1.Introduce

WSS series of 3PE heat shrinkable wraparound sleeves(www.heatshrinkfactory.com) are consist of a radiation cross-linked heat shrinkable backing coated on the inside with a heat activated adhesive. While the modified polyethylene material of the backing offers superior mechanical protection, the specially formulated adhesive offers excellent corrosion protection under demanding conditions.Used in conjunction with the proprietary epoxy primer,the 3 layer system is the choice of discerning clients who need long term corrosion protection.

2.Applied Condition

Temperature Degree | WSS60 | WSS80 |

Max Operating Temperature | 60℃ | 80℃ |

Suitable Coating | PE,FBE,PP | PE,FBE,PP |

Preheat Temperature to Steel | 75℃ | 85℃ |

Rust Cleaning Degree | Sa2.5,St3.0 | Sa2.5,St3.0 |

3.Technical Data

Property | Test Method | WSS60 | WSS80 | |

Epoxy Primer | ||||

Solid Content(%) | ASTM D6980 | 99.5 | 99.5 | |

Cathodic Disbonding (65℃,48h) (mm) | DIN EN12068 | 8 | 8 | |

Backing | ||||

Tensile Strength (psi) | ASTM D638 | 2600 | 2900 | |

Elongation (%) | ASTM D638 | 550 | 550 | |

Hardness Shore D | ASTM D2240 | 45 | 45 | |

Shrink Force (psi) | ASTM D638 | 35 | 35 | |

Dielectric (KV/mm) | ASTM D149 | 20 | 20 | |

Volume Resistance (Ω.cm) | ASTM D257 | 1.0x1016 | 1.0x1016 | |

Water Proof (%) (WT) | ASTM D570 | <0.1 | <0.1 | |

Adhesive | ||||

Softening Point(℃) | ASTM E28 | 103 | 112 | |

Lap Shear (N/cm2 )@23℃ | ASTM D1002 | 200 | 400 | |

Lap Shear (N/cm2 )@80℃ | DIN EN12068 | 20 | 11 | |

Installed Product | ||||

Peel Strength (N/cm)@23℃ | DIN EN12068 | 65 | 85 | |

Impact Resistance(J) | DIN EN12068 | >15 | >15 | |

Indentation Resistance (mm) | DIN EN12068 | >1 @60℃ | >1@80℃ | |

Cathodic Disbonding (mm rad) | DIN EN12068 | <15 | <15 | |

Resistance to thermal Aging | DIN EN12068 | 100d @60℃ | 100d @80℃ | |

Tensile Strength Ratio | DIN EN12068 | 0.9 | 0.9 | |

Elongation Ratio | DIN EN12068 | 0.9 | 0.8 | |

Please contact us for more details