Twin Screw Extruders for Lab and R&D

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | DDP,CIP |

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 200 sets /month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Power: | Electronic |

| Usage: | Plastic Testing Machine |

| Brand Name: | FYI |

| Power: | AC380VNE,14A,E≤4Ω |

| Delivery time: | 3-4 weeks |

| Warranty: | one year |

| Standard: | please check with us |

| Certificate: | CE certificate |

| Dimension: | 1,950×500×1,500mm |

| Gross weight: | 350kg |

| H.S.CODE: | 90248000 |

| Usage: | of engineering plastics |

| Origin: | Made in China |

| Production Capacity: | 200 sets /month |

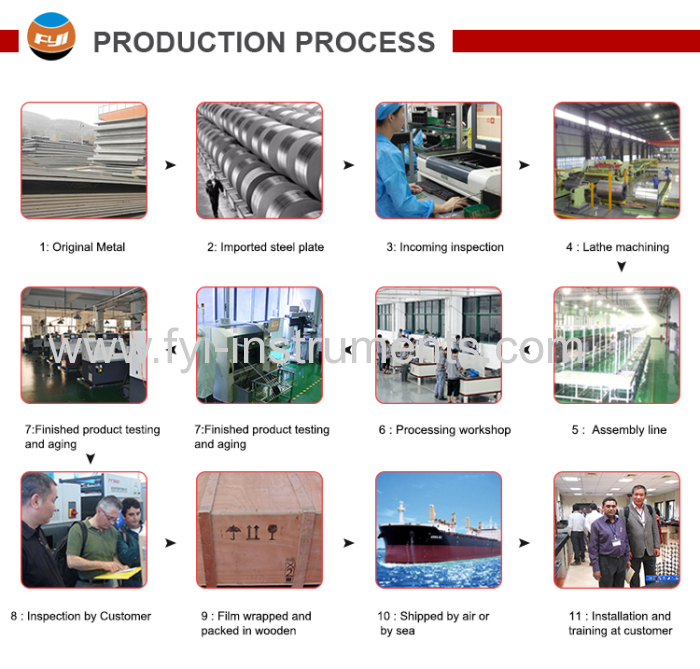

| Packing: | plywood package |

| Delivery Date: | 3-4 weeks |

Product Description

MODEL NO.:

DW5210 Twin Screw Extruders for Lab

APPLICATION:

DW5210 Lab Twin Screw Extruder can be applied to the mixing, plasticizing and extrusion of engineering plastics, modified plastics, masterbatch and other high polymers with the features of uniformly dispersed, plastics coloring and filling to modify. It can be used in laboratory tests, quality control, teaching research and small-scale production.

FEATURES of Twin Screw Extruders for Lab:

l The mandrel of screw is made of 40CrNiMoA chrome-molybdenum alloy tool steel, treated by nitriding, hardening and tempering, chromium plating and super-fine grinding, resistant to corrosion.

2 The combination of screw components is building block type, can be arranged according to the technology of material. Different shear force and mixing effect can be achieved for production of diverse materials;

3 Charging barrel adopts bimetallic material, hard alloy wear-resistant inner sleeve with replaceable lining and multi-section barrel assembly arranged according to different functions;

4 High precision temperature sensors to monitor the melt temperature change;

5 PLC programmable LCD touch control panel, with all parameters are freely controlled and extruding process are dynamically displayed;

KEY SPECIFICATIONS:

1 Control mode | PLC type |

2 Output | Approx. 1~10kg/h (depending on the technique formula) |

3 Screw diameter | 20mm, 25mm or 30mm |

4 Screw L/D | 40 : 1 |

5 Screw rotating speed | 0~120 rpm, adjustable |

6 Direction of screws | Parallel co-rotating |

7 Heating section | Five cast aluminum heating sections for charging barrel, one heating section for head, covered by stainless steel safety fan cover |

8 Cooling device | Charging barrel full sections use circulating water cooling system |

9 Drive power | 2.2kw gear reducer motor |

10 Feeding device | 0~50rpm adjustable speed screw forced feeding |

11 Power supply | AC380V, 50Hz, 3 phase |

12 Dimensions | 1,950×500×1,500mm (L×W×H) |

13 Weight | Approx. 350kg |

Twin Screw Extruders for Lab STANDARD CONFIGURATIONS:

No. | Item | Quantity |

1. | Lab twin screw extruder | 1 set |

2. | Die (Please specify before order) | 1 pc |

3. | Tray | 1 pc |

OPTIONAL ACCESSORIES:

No. | Item |

1. | Die (Please specify before order) |

2. | Cooling water trough |

3. | Particle cutting device |

ELATED PHOTES :

ISO AND CE certificate :