YG139C-J Filament Yarn Evenness Tester

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,DAP |

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 300 sets/month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Usage: | Textile Testing Instrument |

| Power: | Electronic |

| Brand Name: | FYI |

| Power supply: | Manual |

| Deliery time :: | 3-4weeks |

| Certificate: | CNAS,CO |

| Gross weight: | 75KG |

| Conuntry of Origin: | Anhui |

| Brand :: | FYI |

| standard: | check with us |

| Production Capacity: | 300 sets/month |

| Packing: | plywood package |

| Delivery Date: | 3-4 weeks |

Product Description

Filament Yarn Evenness Tester

Model No.

YG139C-J Filament Yarn Evenness Tester

Application:

YG139C-J Filament Yarn Evenness Tester is used to inspect and analyze the mass variation in filament yarns with mechanical twisting technology and the idea of modulus design. Faults on various devices or processes used in the procedure of manufacturing filament yarns can be tracked or diagnosed by analyzing the curve of wavelength-spectrogram, unevenness curve, and variance length and statistic data.

Filament Yarn Evenness Tester

Features:

Specialized ×24 capacitance detector for inspecting filament yarns with high precision;

Adopt an industrial processor as host processor, equipped with specialized signal-processing module and well-adapted to environment;

Block-designed whole structure and software system with excellent expansibility;

With self-designed twisting device;

Automatic yarn feeder without extra tools;

High-speed servo system made in Switzerland for twisting;

Visualized operation of steplessly adjusting the twisting speed, accurate and intuitive, can automatically save twisting parameters of varieties, easy to operate;

Completely-digital speed adjusting system, automatic roller's movement and extended roller's service life;

Be able to store unevenness curves, shrink or enlarge them according to several scales;

Be able to directly measure the length of any point on any unevenness curve by using the unique electronic ruler designed by our company, which is convenient to correctly analyze faults on devices or processes with the help of spectrogram;

Synchronously output conventional test results and those of various inhibition, half-inhibition and segments;

Test results are stored in a database, so the user can classify, analyze and rapidly retrieve them;

Be able to insert any test without affecting other tests;

The technology of data protection and restoration can effectively protect various data reports stored in computer and rapidly solve any breakdown caused by the software or hardware; Be able be equipped with automatic yarn feeder to realize automatic test and to improve the testing efficiency.

Number of slots on capacitance detector 4

Application range Various chemical filaments

Count range 10~1670dtex

Testing speed 25m/min, 50m/min, 100m/min, 200m/min and 400m/min

Twisting speed 0~30000rpm

Test time 0.5~20min, settable

Test bobbins per group Up to 24 bobbins

Measuring range of CV% 0.00~99.99%

Statistics in data report Mean value/km

Variance-length curve Cutting length from 0.01m to 1000m

Measuring range of deviation rate DR% 0~99.99%

Referent length and limit 1m±5%

Spectrogram wavelength 25px to 3011m (Max. test length 10000m for single test)

Spectrogram channels 86 (standard) and 172 (fine)

3D spectrograms 1~12 pieces per screen

Display scale of variance-length curve 400%, 100%, 50%, 25%, 12.5% and 6.25%

Count frequency curve count frequency distribution diagram within the range of ±100% relative to the mean count

Input pressure of compressed air 0.15~0.6Mpa

Room climate (20±3)℃

(65±5)%

ower supply AC220V±10%, 50Hz, ≤600W

Weight 75kg

Specifications:

Standard deviation S

Coefficient of variation CV

95% confidence interval

Max. value

Min. value

Standard configuration:

No. | Item | Quantity |

1 | Detector | 1set |

2 | Industrial computer with specific hardware | 1pcs |

3 | Displayer | 1pcs |

4 | Laser Jet printer | 1pcs |

5 | Filament bobbin holder | 1pcs |

Optional Accessories:

No. | Item |

1 | Airflow adjusting control box for filtering and drying compressed air and for precisely adjusting airflow |

2 | Special working table for evenness tester |

3 | Automatic yarn feeder for max. 12 bobbins |

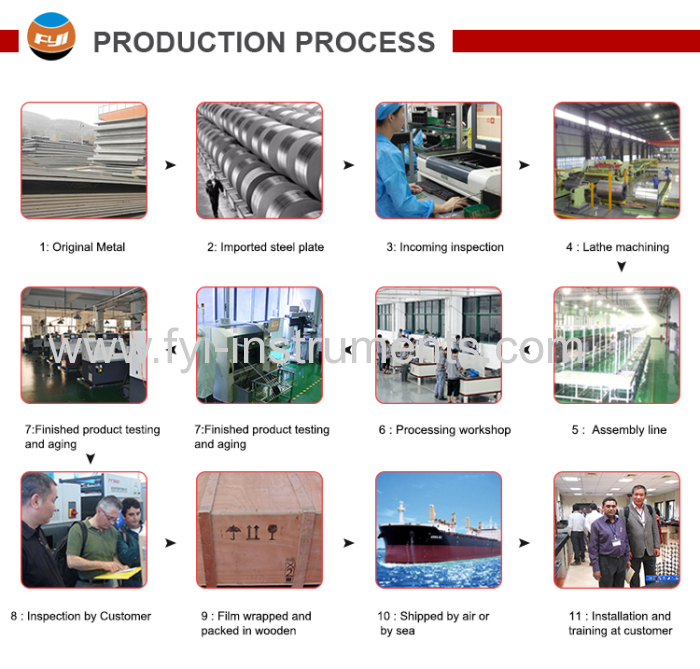

RELATED PHOTES :

ISO AND CE certificate :