HTHP Cone yarn dyeing machine

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | Paypal, L/C, D/A, T/T, WU |

| Supply Ability: | 100Sets/Month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Model No.: | QR241C |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Usage: | Textile Testing Instrument |

| Power: | Electronic |

| Brand Name: | FYI |

| Power: | Electric |

| Delivery time: | 3-4 weeks |

| Display: | LCD |

| Package: | Woode Case |

| H.S.CODE: | 84514000 |

| Voltage: | 220V,60HZ |

| Gross weight: | 2000KG |

| Neg weight: | 1800KG |

| Brand: | FYI |

| Capactity: | 50 SETS/month |

| Production Capacity: | 100Sets/Month |

| Packing: | Plywood pacakge |

| Delivery Date: | 3-4weeks |

Product Description

HTHP Cone yarn dyeing machine

MODEL NO.

QR241C serials HTHP Cone yarn dyeing machine

Application:

QR241C is a HTHP Cone yarn dyeing machine designed for factory use with high temperature and high pressure. It can be applicable for cotton yarn, polyester yarn, wool yarn etc. Other forms samples such as sliver, lea yarn, bulk fiber, viscose, nylon zipper, ticking buckle tape also can be treated after change dyeing frame.

Related Standards:

STANDARDS | GB | ISO | ASTM |

Note: this HTHP Cone yarn dyeing machine can conform to but not limit to all the standards above, for more standards conformance, please contact us.

Features:

l Integral type heat exchanger, centrifugal pump and 180°plate type reversing arrangement.

2 No external circulation pipeline, saving space more than 20%;

3 The main pump's motor is controlled by transducer and the water volume can be adjusted steplessly to accord with the synchro dyeing requirement by technological curves;

4 Unique, stable and reliable reversing arrangement. When the liquid flow is changing its direction the main pump don't stop and this increases liquid's circulation times to raise dyeing quality;

5 Advanced computer controller can display temperature curve, procedure and output, etc;

6 Fully automatic dyes dosing, water feeding, draining, heating, temperature keeping, cooling and cleaning, can meet the dyeing technology requirement;

7 Low bath ratio(1:6~1:7), saving dyes, auxiliary agent, steam and water. Much less waster discharging;

8 Dyeing vessel and all the parts in contact with dye liquid are all made of high quality stainless steel;

9 Control the liquid level is controlled by high-precision differential pressure transducer sensor;

10 Main vessel equipped with automatic pressure and pressure relief device.

Key Specification:

1 Design pressure 0.44MPa

2 Max working pressure 0.4MPa

3 Design temperature 140℃

4 Max working temperature 135℃

5 Heating rate 20~130℃,about 30 minutes (saturated steam pressure:0.7MPa)

6 Cooling rate 130~80℃,about 20 minutes (cooling water pressure: 0.3MPa)

Φ4.5mm,Φ8.0mm,Φ14.5mm,Φ26mm)

7 Power supply 380V

9 Dimension: 2×3×2m (L×W×H)

Model | Bobbin layers | Max capacity (KG) | Main pump power(kW) | Lifting height (mm) |

QR241C-40 | 4 | 12 | 4 | 2770 |

QR241C-45 | 4 | 16 | 5.5 | 2990 |

6 | 24 | 7.5 | 3670 | |

QR241C-50 | 5 | 25 | 7.5 | 3340 |

6 | 30 | 7.5 | 3680 | |

QR241C-55 | 6 | 36 | 7.5 | 3680 |

QR241C-65 | 7 | 56 | 11 | 4345 |

QR241C-75 | 7 | 84 | 15 | 4395 |

9 | 108 | 18.5 | 5140 | |

QR241C-90 | 7 | 126 | 18.5 | 4510 |

9 | 162 | 22 | 5190 | |

12 | 216 | 30 | 6210 | |

QR241C-100 | 7 | 154 | 22 | 4560 |

9 | 198 | 30 | 5240 | |

12 | 264 | 37 | 6260 | |

QR241C-120 | 7 | 252 | 37 | 4980 |

9 | 324 | 37 | 5660 | |

12 | 432 | 45 | 6680 | |

QR241C-140 | 7 | 322 | 37 | 5120 |

10 | 450 | 45 | 6140 | |

12 | 522 | 55 | 6820 | |

QR241C-170 | 7 | 476 | 45 | 5640 |

10 | 680 | 55 | 6660 | |

12 | 816 | 75 | 7340 | |

QR241C-200 | 9 | 972 | 90 | 6590 |

11 | 1188 | 110 | 7270 | |

12 | 1296 | 110 | 7610 | |

QR241C-220 | 17 | 2125 | 185 | 10000 |

Standard configuration:

No. | Item | Quantity |

1 | Main machine | 1 set |

2 | Control cabinet | 1 set |

2 | Bobbin yarn dyeing frame | 1 pcs |

Optional Accessories:

No. | Item | Quantity |

1 | Pretreatment vessel, transport pump, stirring system | |

2 | High-temperature emission system | |

3 | Dyeing frame (loose fiber, beam, lea yarn, etc) | |

4 | Progressive dosing system | |

5 | Main pump flow control system | |

6 | Secondary feed water and drain system |

Good service and quantity .

A. We supply one year warranty and 12 hours service per day .

B. Our skilled engineer can go to your company for installation service

C. Our HTHP Cone yarn dyeing machine adopts top quality material including imported parts, most of the critica HTHP Cone yarn dyeing machine is component are adopting first class brand .

D. Our company passed ISO and have strict quality control before delivery goods

E. We can customized and also supply OEM service

F.. We also can supply different language user's manual . The

user manual of Programmable UV Aging Cabinet can help you operate our machine easily.

G ; we supply operation video if customer need it . .

Payment and delivery :

A..We accept payment such as TT , Western union, and L/C,DP etc . you can contact with us if you need

B. Normally we can delivery time in 3-4 weeks it depend on we have stock or not .

FAQ

Q: Are your company a trading one or a factory?

A:Factory + trader , 30 years focusing on test instruments field

Q What's about delivery time ?

A: Generally about 2-3 Weeks , If we have stock , we can arrange shipment within 3 days after re-tester in our factory , Some machine need customized. Deliver time is longer .

Q: What about the warranty with after - sales services?

A: The testing machine is guaranteed for 12 months by Hefei Fanyuan Instrument

of course .we can help you to repair your problem controller freely ,even it's not from our factory.

After the warranty, the professional after-sale service team will provide perfect technical support and help customer solve problems encountered while using our product, handles guest problems and complaints in a professional and timely.

Q:What about services and quality?

A:Each HTHP Cone yarn dyeing machine must be carried out 100% quality examination and test when shipping and delivery goods.

Each of our product provide video training to show you how to install & operate.

We can arrange engineer to train the operation of equipment to customer's company when you need.

our products are widely recognized and trusted by users.

RELATED PHOTES :

EXHIBTIONS

CUSTOMER

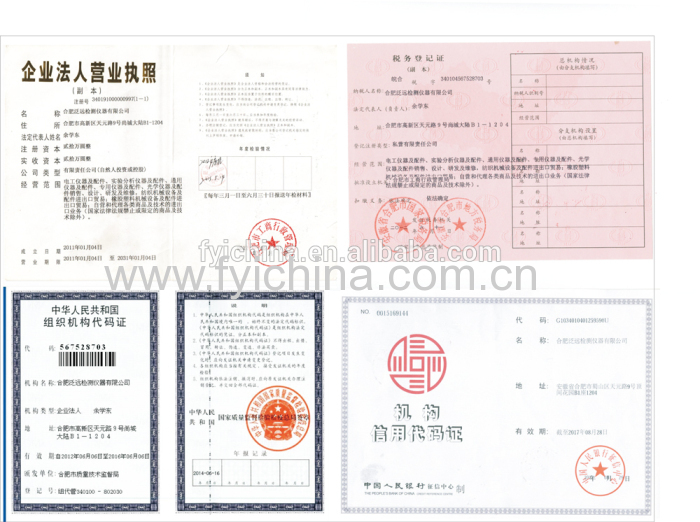

CERTIFICATE