Salt Spray Test Chamber ASTM B117

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | DAP,CIP |

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 1000sets/month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Model No.: | JYWX-90B |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Usage: | Auto Testing Machine |

| Power: | Electronic |

| Brand Name: | FYI |

| M.O.Q: | 1PCS |

| Orginal: | Made in China |

| Certificate: | CNAS ,CO |

| power: | 220v ,50hz |

| Capacity: | 100 sets/Month |

| Hot product: | Newly design |

| After-sale service: | Technician can go abroad |

| H.S.CODE: | 90248000 |

| Brand: | FYI |

| Delivery time: | 4-6 weeks |

| Production Capacity: | 1000sets/month |

| Packing: | standard packaging |

| Delivery Date: | 3-4 weeks |

Product Description

Salt Spray Test Chamber ASTM B117

MODEL NO.

JYWX series Salt Spray Test Chamber ASTM B117

APPLICATION

Salt Spray Test Chamber ASTM B117 is used to create and maintain the salt spray (fog) test environment, and test the anti-corrosion quality of the materials surfaces.

The Salt Spray Fog Test Chamber is a specialized test used to evaluate the resistance to corrosion of paints, coatings, and metal structures as well as effects on electrical systems. Our chambers provide exposure to a salt intensive atmosphere at temperatures matching the proper specification.

STANDARDS

STANDARDS | ISO 9227 | GB/T 10125 | ASTM B117 |

Note: this Salt Spray Fog Test Chamber can conform to but not limit to the standards above, for more standards conformance, please contact us.

KEY SPECIFICATION

Model | JYWX-60B | JYWX-90B | JYW-120B | JYWX-160B | JYWX-200B |

Working chamber size (cm) | 60*40*45 | 60*90*50 | 80*120*50 | 160*50*100 | 120*200*60 |

Dimension (cm) | 110*109*675 | 84*145*120 | 133*207*125 | 247*132*144 | 125*280*160 |

Power (kw) | 2.0 | 2.0 | 3.8 | 3.8 | 5.3 |

Chamber temperature range | room temperature+5℃~50℃ | ||||

Saturator temperature range | room temperature +5℃~63℃ | ||||

Temperature fluctuation | ≤±0.5℃ | ||||

Temperature unevenness | ≤±1℃ | ||||

Air pressure | 0.2~0.4MPa | ||||

Spray pressure | 1.00±0.01kgf/cm2 | ||||

Salt fog condensation speed | 1~2mL/2000px2.h | ||||

Spray cycle time range | 0~999h, H,M,S (programmable) | ||||

Testing time setting | 0~999h, H,M,S (programmable) | ||||

Spraying method | pneumatic method, continuous or discontinuous adjustable | ||||

Specimen rack | 20±5° | ||||

Power supply | AC220V 50Hz | ||||

FEATURES

Ø Test methods:

Neutral Salt Spray (NSS) test, Salt Spray (SS) test, Acetate Salt Spray (ASS) test, Copper accelerated Acetate Salt Spray (CASS) test etc.

Ø Cabinet materials:

1 Chamber and liner materials are imported high-strength and corrosion-resistance PVC plastic board, flat and smooth surface, anti-agent, anti-corrosion, easy to clean and without leakage;

2 Chamber cover materials are imported high quality PVC transparent plastic board and easy to view specimen under testing situation;

3 Cabinet body and chamber cover adopts water seal to avoid salt fog leakage;

Ø Spray system:

4 Adopt tower type sprayer (the height of tower tip is adjustable), small fog particles, nature subsidence, nozzle without salt crystalline settlement is adjustable;

5 Spray fog is two stage regulators, and considering oil extraction function;

6 Salt water is storage as built-in tank with large capacity, and equipped with preheating function;

7 Equipped with quartz Water filter to avoid impurity material block up nozzle and stop test;

8 Salt water tank with water high and low water level display.

Ø Control system:

9 Temperature controller: high accuracy digital temperature controller with high temperature control accuracy, run stable and without shift when long run;

10 Time relay: 1~9999h adjustable, double digit time relay with spraying or stop spraying time in 1~999h adjustable;

l1 Implementation elements: schneider AC contactors, small relay and solid state relay;

12 Gas system: stable and reliable gas path elements.

Ø Protection system:

13 Chamber body over-temperature protection

14 Chamber body low water level protection

15 Saturator low water level protection

16 Saturator over temperature protection

17 Water level low water level notice

18 Water level high water level notice

19 Test end notice

20 Auto shut down when over load, power leakage etc.

Ø Installation environment:

21 Environment temperature: 5℃~+25℃(average temperature is≤25℃ in 24hours)

22 Relative humidity: ≤85%R.H

23 Leave at least 1250px space around machine.

STANDARD CONFIGURATION

No. | Item | Quantity |

1 | Main machine | 1set |

2 | Air pipe | 1pcs |

3 | Measuring glass | 1pcs |

4 | Bucket | 1pcs |

5 | Connector | 1pcs |

6 | PH test strips | 1set |

7 | sodium chloride | 2set |

8 | V-type sample rack | 1set |

10 | Round stick | 1set |

Good service and quantity .

A. We supply one year warranty and 12 hours service per day .

B. Our skilled engineer can go to your company for installation service

C. Our .Salt Spray Test Chamber ASTM B117 adopts top quality material including imported parts, most of the critical component are adopting first class brand .

D. Our company passed ISO and have strict quality control before delivery goods

E. We can customized and also supply OEM service

F.. We also can supply different language user's manual . The

user manual of .Salt Spray Test Chamber ASTM B117 can help you operate our machine easily.

G ; we supply operation video if customer need it . .

Payment and delivery :

A..We accept payment such as TT , Western union, and L/C,DP etc . you can contact with us if you need

B. Normally we can delivery time in 3-4 weeks it depend on we have stock or not .

FAQ

Q: Are your company a trading one or a factory?

A:Factory + trader , 30 years focusing on test instruments field

Q What's about delivery time ?

A: Generally about 2-3 Weeks , If we have stock , we can arrange shipment within 3 days after re-tester in our factory , Some machine need customized. Deliver time is longer .

Q: What about the warranty with after - sales services?

A: The testing machine is guaranteed for 12 months by Hefei Fanyuan Instrument

of course .we can help you to repair your problem controller freely ,even it's not from our factory.

After the warranty, the professional after-sale service team will provide perfect technical support and help customer solve problems encountered while using our product, handles guest problems and complaints in a professional and timely.

Q:What about services and quality?

A:Each Salt Spray Fog Test Chamber must be carried out 100% quality examination and test when shipping and delivery goods.

Each of our product provide video training to show you how to install & operate.

We can arrange engineer to train the operation of equipment to customer's company when you need.

our products are widely recognized and trusted by users.

RELATED PHOTES :

EXHIBTIONS

CUSTOMER

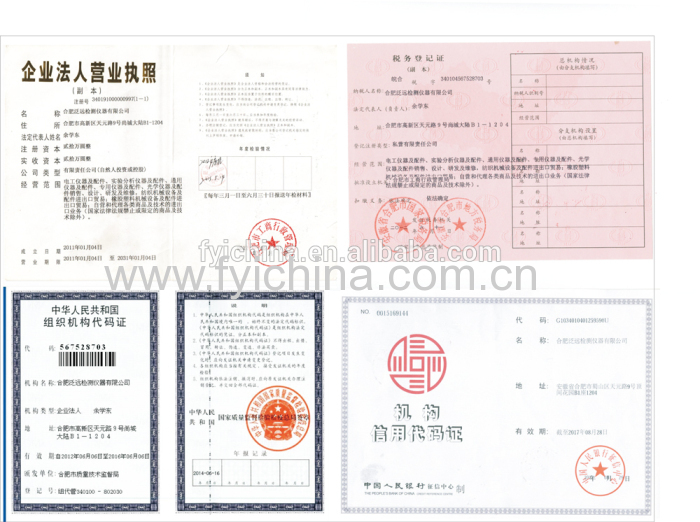

CERTIFICATE