Sweating Guarded Hotplate Test CLO and RET Testing Machine

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, D/A, T/T, WU |

| Supply Ability: | 100Pcs |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Model No.: | DW259A |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Usage: | Textile Testing Instrument |

| Power: | Electronic |

| Brand Name: | FYI |

| MODEL: | DW259A |

| Brand : FYI: | Color : White |

| Voltage:: | 220V,60HZ |

| Production capacity: | 100sets |

| Net weight: | 350 KG |

| Gross weight : 400 kG: | Dimension :1200×1500×2200mm |

| Display: | LCD |

| Power: | Electric |

| Certificate: | CE ,CNAS |

| H.S.CODE: | 90248000 |

| Production Capacity: | 100Pcs |

| Packing: | plywood package |

| Delivery Date: | 3-4 weeks |

Product Description

Thermal Water Vapor Resistance Tester

MODEL NO.

DW259A Thermal Water Vapor Resistance Tester

APPLICATION

DW259A Thermal Water Vapor Resistance Tester is often referred to as "skin model" to produce accurate, repeatable measurements of thermal resistance and water vapor resistance of textiles, fabrics, films, coatings, foams and leather including multilayer assemblies, such as clothing, quilts, sleeping bags, upholstery and similar textile or textile-like products under steady-state conditions.

The specimens to be tested is placed on an electronically heated porous plate with conditioned air ducted to flow across and parallel to its upper surface.

Thermal resistance(Rct): a quantity specific to textile materials or composites which determine the dry heat flux across a given area in response to a steady applied temperature gradient, expressed in square meters kelvin per watt.

Rct=(Tm-Ta)*A/(H-ΔHc)

Tm: the temperature of the measuring unit, in degree Celsius;

Ta: the air temperature in the test enclosure, in degree Celsius;

A: the area of the measuring unit, in square meters;

H: the heating power supplied to the measuring unit, in watts;

ΔHc: the correction term for heating power;

Water vapor resistance(Ret): a quantity specific to textile materials or composites which determines the "latent" evaporative heat flux across a given area in response to a steady applied water-vapor pressure gradient, expressed in square meters pascal per watt.

Ret=(Pm-Pa)*A/(H-ΔHe)

Pm: the saturation water-vapour partial pressure, in pascals, on the surface of the measuring unit at temperature Tm;

Pa: the water-vapor partial pressure of the air in the test enclosure at temperature Ta;

A: the area of the measuring unit, in square meters;

H: the heating power supplied to the measuring unit, in watts;

ΔHe: the correction term for heating power for the measurement of water-vapor resistance Ret;

Water-vapor permeability index, imt: ratio of thermal and water-vapor resistance;

imt=S*(Rct/Ret)

S equals to 60Pa/k;

Water vapor permeability, Wd: characteristic of a textile material or composite;

Wd= 1/(Ret*ФTm);

ФTm: the latent heat of vaporization of water at the temperature Tm of the measuring unit;

For example, When Tm=35℃, ФTm=0.672W·h/g.

RELATED STANDARDS

STANDARDS | GB/T 11048 ASTM F1868 | ISO 11092 ASTM D1868 | ASTM D1518 |

Note: this fabric thermal and water-vapour resistance meter can conform to but not limit to the standards above, for more standards conformance, please contact us.

FEATURES

l Use a large touch panel (OMRON,Japan) to display and a microcomputer to control and deal with data automatically;

2 Display measuring results and dynamic curves;

3 In-built programmable testing programs, meeting requirements of related GB/T, ISO standards;

4 With lateral and lower thermal guard rings;

5 Copper test plate and guards with ultra-stable resistance wire heating for uniform heat flux;

The coefficient of radiation of the test plate surface is greater than 0.4, measured at 20℃, between the wavelengths 8 μm to 14 μm, with the primary beam perpendicular to the plate surface and the reflection hemispherical.

6 Use a step motor to move the test plate and thermal guards up or down, stably and accurately;

7 Variable speed fans and air velocity sensor;

8 Use a closed loop control system to supply water automatically and precisely;

9 Use PLC as central control system and an closed loop control system to control temperature and humidity automatically;

l0 Use the surface evaporation method to produce water vapor from saturated steam;

11 Sweating guarded hotplate system is compactly designed so it easily fits into climate-controlled chamber. If available, it can be moved out of the existing climate-controlled chamber and the chamber can be replaced;

KEY SPECIFICATION

l Test method Sweating guarded-hotplate

2 Display mode LCD touch panel

3 Measurable results Thermal resistance Rct,

water-vapor resistance Ret, water-vapor permeability index imt, water vapor permeability Wd, partial discharge (corona), thermal transmittance

4 Measuring range of Rct (thermal resistance) 0.015~2.0m2K/W

5 Measuring range of Ret (water vapor resistance) 5~1000m2Pa/W

6 Test plate size 250×250×3mm (L×W×H)

7 Width of thermal guard ring 125mm

9 Range & accuracy of measuring temperature 15℃~50℃±0.1℃

10 Range & accuracy of measuring humidity 30%RH~98%RH±2%RH

11 Range & accuracy of controlling temperatures of measuring unit 20℃~85℃±0.1℃

l2 Up/down range of porous melt plate and thermal guard 0~50mm

l3 Accuracy of feeding water ±0.5mm

14 Inner dimensions of climate controlled chamber 820×820×1100mm (L×W×H)

l5 Temperature range & accuracy in climate controlled chamber 15℃~50℃±0.1℃

16 Humidity range & accuracy in climate controlled chamber 30%RH~98%RH±2%RH

17 Air velocity 0.01~2m/s±0.05m/s

l8 Frequency of measuring air speed 200Hz

l9 Power supply AC 220V 50HZ 1500W

20 Dimensions 1200×1500×2200mm (L×W×H)

21 Weight approx. 400kg

STANDARD CONFIGURATION

No. | Item | Quantity |

1 | Main machine | 1set |

2 | Cellulose membrane used in measuring water vapor resistance | 2pcs |

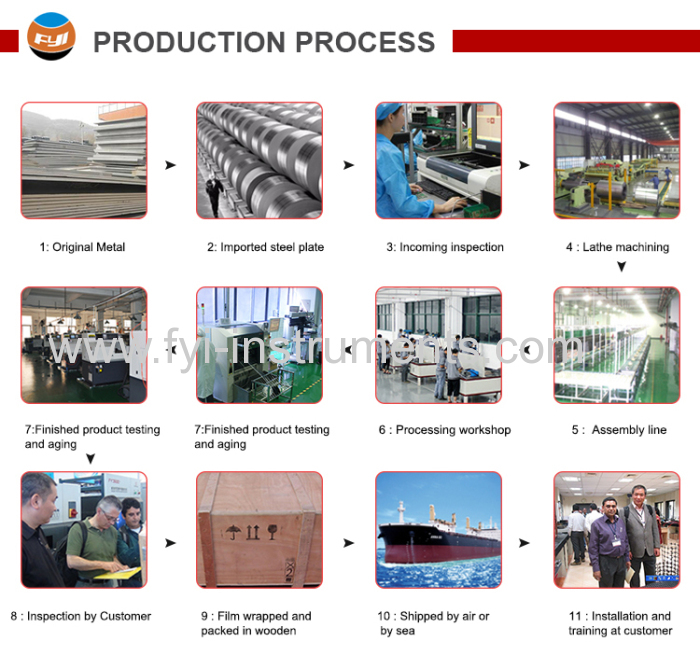

Factory show :