Xenon Weathering Testing Chamber

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | DDP,DAP,CIP,FCA,EXW |

| Payment Terms: | L/C, D/A, T/T, WU |

| Supply Ability: | 100Sets/Month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Model No.: | YG611M |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Power: | Electronic |

| Usage: | Textile Testing Instrument |

| Brand Name: | FYI |

| Power: | Electric |

| Delivery time: | 45 days |

| Display: | LCD |

| Dimension: | 900×650×1800mm |

| Standard: | ISO ,ASTM |

| Gross weight: | 230KG |

| Voltage: | 220V,60HZ |

| Neg weight: | 200KG |

| Textile Sunlight Fastness Tester: | Light Colorfastness Tester |

| Brand: | FYI |

| Production Capacity: | 100Sets/Month |

| Packing: | Plywood pacakge |

| Delivery Date: | 6-8weeks |

Product Description

Xenon Weathering Testing Chamber

MODEL NO.

YG611M

Application:

YG611M Xenon Weathering Testing Chamber. To determine the color fastness and aging to sunlight, weather resistance, compoundcolor fastness to sunlight-perspiration of colored textile, leather, leatheroid, plastic, etc, by setting various parameters of irradiance, temperature, humidity, spray to simulate natural condition in lab. Be able to control irradiance real-time, automatically inspect and compensate irradiance, temperature, humidity.

Related Standards:

Note: this Xenon Weathering Testing Chamber can conform to but not limit to all the standards above, for more standards conformance, please contact us.

Features:

Presetting various specifications, Custom program capability, meet diverse range of standards, including AATCC, ISO, BS, JIS etc;

Automatic compensating system (PATENT) control the Xenon Lamp Power;

EviewTM touch screen, indicate the condition of chamber at real-time, be able to presetting irradiance, temperature (BPT, BST, chamber), humidity, and plot dynamic curve of them. The operator simply selects the required test module and test standards; English user interface, diagram indicate condition of chamber, easy to use;

PLC (OMRONTM) control, powerful program and storage property, save the parameters when interrupt of power supply.

Low running cost, latest energy-saving technology, 2.5KWH/hour, no need for extra regulation;

Manageable size is most appropriate to testing fabric samples, and easy access to sample holder;

Chamber temperature control, irradiation temperature, and heater raise the temperature, air conditioning refrigeration.

Irradiation control, light irradiance sensor monitor, digital setting, automatic compensating system, stepless adjustable.

Ultrasonic humidification system makes spray water even and low noise. Saturated steam humidifying, industrial refrigerating machine dehumidifying, and close loop control the humidity.

Dual redundant circuit designing to assure unit to work consistently and reliably;

Custom program capability and storage for additional user-defined tests.

Built-in diagnostics and warnings, automatic prompt when lamp or optical filters require changing. Multi-position sensor to supervise working condition, temperature, humidity, fan, xenon lamp, and door to chamber, it makes device work properly and reliably;

Use driving clutch to connect turntable and motor, it makes turntable rotate freely and put sample easily without stopping unit;

Safety monitoring point: irradiance, air flow, water level, chamber temperature, chamber door, over current, over voltage.

Power supply Ac220V±5% 50Hz 20A 4500W

Irradiation Source: 3000W Air-cooled Long Xenon Arc Lamp

Average Lamp Life: 1500 hours

Rack Rotating Speed: 1-5r/min

Diameter of Sample Rack 175mm

Specimen Holder Exposure Area: 100×45mm(ISO) 140×70mm(AATCC)

Max Exposure Area of Specimen 450cm2

Chamber Temperature Range 25℃~50℃±2℃

BST 40℃~85℃±1℃

BPT 40℃~80℃±2℃

Humidity Range 25%RH-85%RH ±5%

Irradiance range

Wide Bandwidth Measurement: (35~55)±1W/m2 @300~400nm

Narrow Bandwidth Measurement: (0.550~1.300)±0.02W/m2 @420nm

Full bandwidth Measurement: no less than 700w/m2@290~800nm

Cooler Power and Cooling Capacity 1000W, 2400cal/hour

Instrument Dimension 900×650×1800mm(L×W×H)

Instrument Weight 230kg

Key Specification:

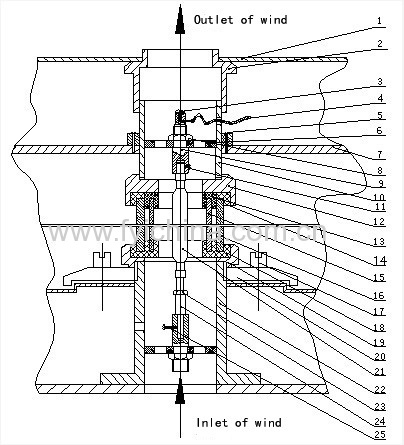

Structure inside the Exposure Chamber:

1. Coping 2. Outlet of wind 3. Bolt 4. Cable

5. Bolt of sleeve 6. Insulation covering 7.Upper board 8. Locknut

9. Upper covering head of xenon arc lamp 10. Sleeve 11. Bolt

12. Impacting tray 13. Outer ring seal 14. Inner ring seal 15. Light filter

16. Glass tube 17. Sample shelf 18. Rubber ring 19. Lower tray

20. Sample turntable 21. Xenon arc lamp 22. Main sleeve 23. Locknut

24 Lower covering head of xenon arc lamp 25 Bolt

Standard configuration:

No. | Item | Quantity |

1 | Main machine | 1 set |

2 | Xenon lamp kit Including: Xenon lamp, CFQ glass tube, metallic connector | 1 pcs |

3 | AATCC specimen holder (140×70mm)one set for 5 pcs | 1 set |

4 | ISO Specimen holder (100×45mm)one set for 10 pcs | 1 set |

5 | BPT | 1 set |

6 | BST | 1 set |

7 | Gray scale | 1 set |

8 | blue wool standard | 1 set |

9 | Latex gloves | 5 pairs |

10 | sunglasses | 1 pcs |

11 | Card stock | 1 pack |

12 | wrench | 1 pcs |

13 | IR filters | 7 pcs |

14 | UV filters | 1 pcs |

15 | Inner hexagonal wrench | 1 pcs |

16 | Water filter | 1 pcs |

17 | Exhaust duct | 1 set |

Optional Accessories:

No. | Item | Quantity |

1 | AATCC Gray scale | 1 set |

2 | AATCC blue wool standard | 1 set |

3 | Irradiance calibration kit | 1set |

4 | Custom light filters | 1set |

Related accessoires photoes :