Popular Mooney rubber viscometer manufacturer

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 200 sets /month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Model No.: | DW5330 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Usage: | Others |

| Power: | Electronic |

| Brand Name: | FYI |

| Power: | 220V,50HZ |

| Delivery time: | 3-4 weeks |

| Warranty: | one year |

| Standard: | ASTM D1646 |

| Certificate: | CE certificate |

| Dimension: | 520×570×1000mm; |

| Gross weight: | 120KG |

| Package: | Wooden case |

| Shipment method: | by Sea |

| Brand: | FYI |

| Production Capacity: | 200 sets /month |

| Packing: | plywood package |

| Delivery Date: | 3-4 weeks |

Product Description

Popular Mooney rubber viscometer manufacturer

MODEL NO.

DW5330 Popular Mooney rubber viscometer manufacturer

APPLICATION

DW5330 Popular Mooney rubber viscometer manufacturer is used for measuring viscosity and relaxation of base rubber, raw rubber stock or rubber mass prevulcanization properties, it also used for measuring viscosity in Mooney value for compounded or uncompounded unvulcanized natural, synthetic or regenerated rubber.

This Popular Mooney rubber viscometer manufacturer has excellent performances including automatic calibration, higher stability. It can perform the following tests: viscosity, scorch and stress relaxation.

STANDARDS

STANDARDS | ASTM D1646 | ISO 289 |

Note: this Popular Mooney rubber viscometer manufacturer can conform to but not limit to the standards above, for more standards conformance, please contact us.

FEATURES

3 testing item: prevulcanization, Mooney viscosity, stress relaxation;

Automatic calibration, high stability;

Excellent repeatability and smoothness of curves;

Steadily temperature control, high heating speed;

Excellent heat preservation, rapid temperature recovery;

Powerful function of processing software, easy to operate;

Automatically data store, possible to printout Excel reports.

Temperature range room temperature~200℃

Temperature fluctuation in die: ≤±0.1℃

Resolution of temperature 0.1℃

Heating speed 16~25℃/min

Torque range 0~200Mv

Torque resolution 0.01Mv

Rotor speed 2±0.02r/min

Dimensions 520×570×1000mm;

Weight about 120kg;

Power AC220~230V, 50/60 HZ, 3A

KEY SPECIFICATION

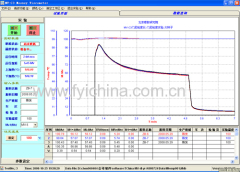

SOFTWARE USER INTERFACE

Testing result of experiment for Mooney viscosity :

MI - Initial Mooney viscosity.

M1+4 - Normal Mooney Viscosity, 1min for preheating, 4mins for testing.

Me - Mooney value obtained upon completion of test.

TR80 – The time when stress relaxation reaches to 80% of Mooney viscosity.

MRe - Mooney viscosity at the end of stress relaxation.

MV-t - Mooney viscosity at time t.

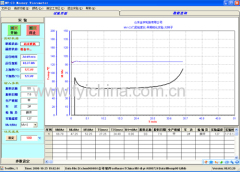

Testing result of experiment for prevulcanization :

MI - Initial Mooney viscosity.

ML - Minimum Mooney viscosity.

M5 - ML+5 Mooney viscosity.

M35 - ML+35 Mooney viscosity.

t5 - Mooney scorch time when the Mooney viscosity is M5, unit: min.

t35 - Mooney scorch time when the Mooney viscosity is M35, unit:min.

MV-t - Mooney viscosity at time t.

△t30 – Increment of vulcanizing time, △t30=( t35- t5)

STANDARD CONFIGURATION

No. | Item | Quantity |

1 | Main machine | 1 set |

2 | Base of main machine | 1 set |

3 | Computer | 1 set |

4 | Printer | 1 set |

5 | Allen wrench | 1 set |

6 | Power cord | 1 pcs |

7 | Signal wire | 1 pcs |

8 | Fuse (3A) | 10 pcs |

9 | Software CD and driver | 1 pcs |

10 | Copper brush | 1 pcs |

11 | Tweezers | 1 pcs |

12 | Cellophane (0.02mm thick) | 5 pack |

13 | O-ring | 50 pcs |

14 | Weight | 1 pcs |

15 | Large rotor( in main machine) | 1 pcs |

16 | Small rotor | 1 pcs |

17 | Wirerope( in main machine) | 5 m |

18 | Sensor bars( in main machine) | 1 pcs |

19 | Air pipe | 2 m |

20 | Product qualification certificate | 1 copy |

21 | User manual | 1 copy |

RELATED PHOTEOS:

RELATED PHOTES :

EXHIBTIONS

CUSTOMER

CERTIFICATE