Automatic Box Making Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C |

| Supply Ability: | 25sets per month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Rigid Box Line, Rigid Box Maker, Rigid Box Making Machine, Automatic Slipcase Making Machine, Automatic Box Grooving Machine |

Product Detail

| Model No.: | HM-ZD600 |

|---|---|

| Means of Transport: | Ocean |

| Box Length Max.: | 600mm |

| Folding-in Depth: | 10-45mm |

| Service: | Engineer available to customer factory |

| Guarantee: | One year |

| Production Capacity: | 25sets per month |

| Packing: | Wooden Case |

| Delivery Date: | 20days |

Product Description

HM-ZD600 Automatic Box Making Machine

Box Making Machine; Rigid Box Making Machine; Paper Box Making Machine; Cell phone Box Making Machine; Chocolate Box Making Machine; Professional manufacturer for rigid box making machine; China Box making machine; cardboard box making machine; mobile phone box making machine; gift box making machine; jewellery box making machine factory

Hongming Machinery special for producing rigid box making machine, rigid box maker, rigid box line, rigid box set up machine.

HM-ZD600 Automatic Box Making Machine is the very first fully auto box machine by our machine. Specializing in mass producing every kinds of big rigid boxes, such as shoe box, cellphone box, shirt box, toy box, tea box, book type box, etc

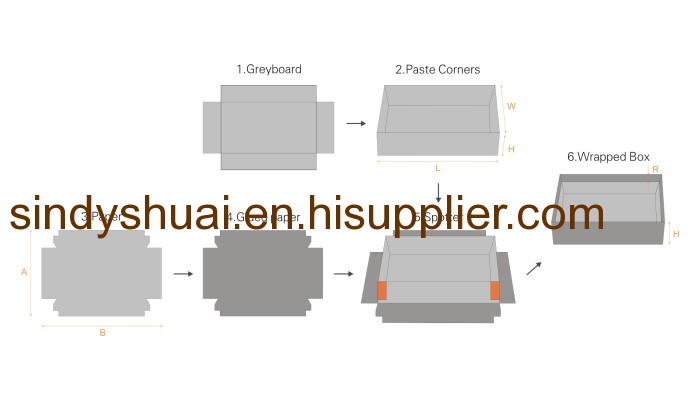

This machine adopts Japanese Panasonice PLC and Man-machine control, electric eye tracing system, hydraulic pneumatic rectifying system, and can automatically feed paper, feed greyboard, paste four corners, spot greyboard, drag box, wrap box, fold corner edge and form box.

1.Suitable for all kinds of rigid boxes in mass production;

2.Employ Japanese Panasonic PLC and man-machine control to automatically form boxes in one process;

3. Computer control with error auto stop and display;

4. Automatically feed paper and greyboard;

5. 24-hours control for glue pre-heating;

6. Automatically cut and heat the tape to paste on the greyboard box's quad stayer (four corners), with independent man-machine control;

7. Spotter by electric eye tracing system and hydraulic pneumatic recifying system to spot correctly (spotting accuracy ≤0.2mm);

8. Conveyor by vacuum suction fan to keep the glued paper from deviating;

9. Wrapper can automatically and continually deliver box, wrap paper, fold corner edge, fold in and form box;

10. Remodel for irregular boxes and plastic boxes (optional);

11. Automatic control system for glue viscosity meter (optional).

Automatic rigid box making machine | HM-ZD600 | |

Paper Sheet Size (B=Length, A=Width) | A ( max.) | 610mm |

A ( min.) | 95mm | |

A ( max.) | 850mm | |

A ( min.) | 180mm | |

Finish product (Box )Size L=Length W=Width H=Height T=Thickness | L ( max.) | 600mm |

L ( min.) | 100mm | |

W ( max.) | 400mm | |

W ( min.) | 50mm | |

H ( max.) | 130mm | |

H ( min.) | 12mm | |

Cardboard thickness (T) | T ( max.) | 3mm |

T ( min.) | 1mm | |

Thickness of Paper(m2/g) | 80g-160g/m2 | |

Folding Edge size ( R ) | 10mm-45mm | |

Speed | 20-30pcs/min | |

Power | 17KW/AC380V | |

Net Weight | 5800kg | |

Machine Dimension | 6800x4500x3300mm | |

Note:

1. The max. size and the min. size of box are determined by the max. and min. size of cover paper.

A( Min.)<W+2H+2T+2R<A(Max.); B( Min.)

2. The production speed of the rigid box machine is determined by the box size, paper and cardboard materials.

3. Seller doesn't provide air compressor. (8 atm=0.808MPA , 7.5KW compressor is needed)