.jpg)

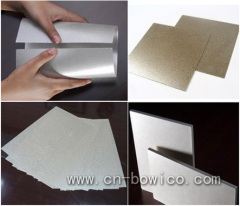

Rigid Mica Sheet

| Min. Order: | 1000 kg |

|---|---|

| Payment Terms: | L/C at sight, T/T, DP |

| Supply Ability: | 8000MT/year |

| Place of Origin: | Hubei |

Company Profile

| Location: | Xianning, Hubei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | PB5662, PJ5662 |

|---|---|

| Brand Name: | PAMICA |

| Production Capacity: | 8000MT/year |

| Packing: | carton or pallet |

Product Description

Pamica rigid mica sheet for heater consist of approximately 90% muscovite or alternatively phlogopite, impregnated with high temperature resistant orgnic silicon resin. It is used as insulating parts for electric toasts, hair dryers, electric irons ,curlers, electric hot combs, strip heaters , baseboard heaters, also for gaskets, and in other appliances and applications where excellent resistance to moisture and thermal, mechanical and electrical properties are required. The products are certified by UL and in conformity with IEC371.

They are offered in five different types to meet the individual requirements of users, providing outstanding electrical insulation at high temperature.

1. PB5661: A special low smoke and blister-free grade. It fully resists the extreme high temperature cycles typically encountered for example, in food grade toasters, micro-wave oven.

2. PB5662: Standard grade for all heating elements of hair dryers, irons, heating oven, band heaters, nozzle heaters, etc.

3. PB5662-G: A higher density grade with smoother surfaces by steel pressing. Most suitable for punching highly detailed pieces or when imprinting is required.

4. PJ5661: A special low smoke and blister-free grade. Softer and more heat resistant. For extreme high temperature application.

5. PJ5662: Standard grade for all heating elements operating in an extreme temperature range.

They are offered in five different types to meet the individual requirements of users, providing outstanding electrical insulation at high temperature.

1. PB5661: A special low smoke and blister-free grade. It fully resists the extreme high temperature cycles typically encountered for example, in food grade toasters, micro-wave oven.

2. PB5662: Standard grade for all heating elements of hair dryers, irons, heating oven, band heaters, nozzle heaters, etc.

3. PB5662-G: A higher density grade with smoother surfaces by steel pressing. Most suitable for punching highly detailed pieces or when imprinting is required.

4. PJ5661: A special low smoke and blister-free grade. Softer and more heat resistant. For extreme high temperature application.

5. PJ5662: Standard grade for all heating elements operating in an extreme temperature range.

Specification:

Standard size: 1000x600mm; 1000x1200mm; 1000x2400mm(max)

Strips and punched parts according to drawings

Thickness: 0.1-1.9mm

Standard size: 1000x600mm; 1000x1200mm; 1000x2400mm(max)

Strips and punched parts according to drawings

Thickness: 0.1-1.9mm

Package:

Package: carton

Size (Lxw): 1000x600mm or 1000x1200mm

Protective package: pallet or wooden case

Package: carton

Size (Lxw): 1000x600mm or 1000x1200mm

Protective package: pallet or wooden case

| Item | PB5662-1 | PJ5662 | PB5662-2 | PB5662-G | Test Standard | |||

| Muscovite | Phlogopite | Muscovite | Muscovite | |||||

| Mica Content* % | 92 | 91.5 | 91.5 | 91.0 | IEC 371-2 | |||

| Bond Content % | 8 | 8.5 | 8.5 | 9.0 | IEC 371-2 | |||

| Density* g/cm 3 | 2.0 | 2.0 | 2.15 | 2.15 | IEC 371-2 | |||

| Fire Resistance | Continuous | 500 C | 500 C | 600 C | 500 C | QB/08* | ||

| Intermittent | 700 C | 800 C | 800 C | 700 C | QB/08* | |||

| Flexural Strength N/mm 2 | >160 | >140 | >180 | >180 | ISO178 | |||

| Dielectric Strength Kv/mm | >20 | >20 | >20 | >20 | IEC243 | |||

| Insulation Resistance ( Ω x cm) | 23 C | >10 17 | >10 17 | >10 17 | IEC 93 | >10 17 | ||

| 550 C | >10 12 | >10 12 | >10 12 | IEC 93 | >10 12 | |||

| Water Absorption (%) | <1 | <1 | <1 | <1 | ISO62 | |||

| Thermal Expansion (10 -6 /K) | Perpendicular to layer | 100 | 100 | 100 | QB/08* | |||

| Parallel to layer | 10 | 10 | 10 | QB/08* | ||||

| Heat Loss at Heating (%) | 500 C | <1 | <1 | <1 | IEC 371-2 | <1 | ||

| 700 C | N/M | <1 | N/M | IEC 371-2 | <1 | |||

| * The content of mica and bond in 0.15 -0.4mm thick mica plate is 92.5% and 7.5%, that in 0.5 -1.0mm thick is 92% and 8%, that in 1.1 -1.95mm thick is 91% and 9%. * The density of 0.2mm below is 1.8g /cm 3 , that of 0.2 -0.5mm thick mica plate is 2.0g /cm 3 , that of 0.6 -1.95mm thick mica plate is 2.15g /cm 3 . * QB/08: Enterprise standard of Pamica | ||||||||

.jpg)