bucket chain gold mining dredger

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 3 sets/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Weifang, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Sand Dredger, De-silter, Gold Panning Boat |

Product Detail

| Model No.: | BCGD8020 |

|---|---|

| Means of Transport: | Ocean, Land |

| Application: | Ore |

| Type: | Others |

| Brand Name: | Chaoyue |

| processing capacity:5t/m: | recovery efficiency:95% |

| moveable: | easy maintenance |

| low price: | low power consumption |

| Production Capacity: | 3 sets/month |

| Packing: | in bulk or in container |

| Delivery Date: | 30 days |

Product Description

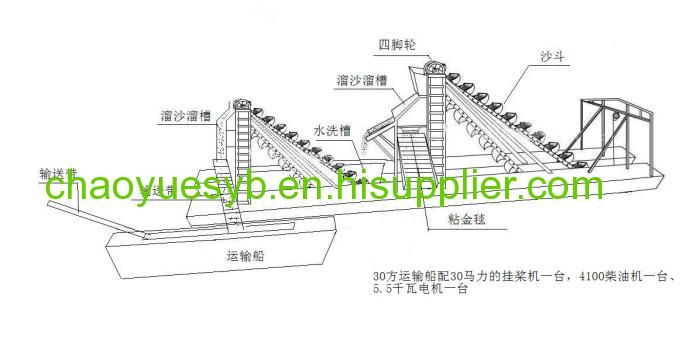

A gold dredger is a placer mining machine that extracts gold from sand, gravel and dirt by water washing

and other mechanical methods.

A large gold dredge uses a mechanical method to dig up material (sand, gravel, dirt, etc.) with steel

"buckets" on a circular, continuous, steel "bucket line" at the front of the dredger. The material is then sorted/sifted with water. On large gold dredges, the buckets dump the material into a steel rotating

cylinder (a special type of trommel called "the screen") sloped downward toward a rubber conveyor belt (the stocker) that carries away oversize material (rocks) and dumps them behind the dredger. The cylinder has

many holes drilled into it to allow under-size material (including gold) to fall into a sluice box. The material that is washed away or sorted out is called tailings. The rocks deposited behind the dredger (by the stocker) are called "tailing piles." The

holes drilled in the screen were intended to screen out rocks (e.g., 3/4 inch holes in the screen sent

anything larger than 3/4 inch to the stocker).

The whole gold dredging procedure consisting of gold ore digging, screening, rough separation and fine concentration can be completed by the high-efficiency, large-capacity dredger, which is an ideal equipment for our customers.

Parameter

Model | Specification(m) | Dredging Depth(m) | Power | Water Flow Rate | Efficiency(%) |

CYH-5 | 3×1 | 4 | 20 | 90-95 | 95-98 |

CYH-60 | 8×1.8 | 40 | 50 | 90-95 | 95-98 |

CYH-80 | 6×1.8 | 37 | 40 | 90-95 | 95-98 |

CYH-160 | 12×5 | 75 | 240 | 90-95 | 95-98 |

CYSW-70 | 13×4.5 | 4-6 | 50 | 60 | 95-98 |

CYSC-120 | 8×5.2 | 4-18 | 110 | 220 | 95-98 |

CYSW-200 | 26×6.5 | 4-20 | 150 | 320 | 95-98 |