High Density Charcoal Briquetting Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 4-18 t/h |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Jaw Crusher, Impact Crusher, Cone Crusher, Mobile Crusher, Roller Crusher |

Product Detail

| Model No.: | FTM series |

|---|---|

| Means of Transport: | Ocean, Land |

| Application: | Others |

| Type: | Others |

| Brand Name: | Henan Fote |

| Name: | High Density Charcoal Briquetting Machine |

| Production Capacity: | 4-18 t/h |

| Motor power: | 37-55 kw |

| Abrasive Resistance: | Good |

| Installation: | Under technical guidance |

| Gurantee: | 1 Year |

| Supply Ability: | 100 sets per month |

| Factory: | 50,000 square meters closed workshops |

| Market: | Africa, Europe, Asia,etc |

| Certifications: | BV,CE,GOST,ISO9001 |

| Production Capacity: | 4-18 t/h |

| Packing: | Standard containers, machine parts are packed in wooden cases. |

| Delivery Date: | 0-20 days delivery |

Product Description

High density charcoal briquetting machine introduction:

1.High density charcoal briquetting machine can press charcoal powder, coal powder and other powder into briquettes.

2.It can press the powders into different shapes by changing different molds.

3.It can produce solid or hollow shaped charcoal.

4.The final charcoal can be used as fuel, BBQ, boiler and so on.

High density charcoal briquetting machine advantages:

1.Different type:roller type,hydraulic type,high pressure type.

2.Strong structure,high briquetting ratio because the excellent design.

3.It can be the single machine or whole production line.

4.Shape can be round,pillow & square shape.

5.Engineer available for installation in customer country.

High density charcoal briquetting machine features:

1.Briquette machine absorbs the advanced technique at home and abroad.

2.Innovative design and reliable quality.

3.Key parts are processed by imported high quality materials.

4.High strength and toughness.

5.Temperature control, durability, adaptability.

6.High production capacity.

High density charcoal briquetting machine technical datas:

| Performance | FTM-360 | FTM-400 | FTM-500 | FTM-650 | |

| Output | hour (t/h) | 4 | 8 | 11 | 18 |

| Annual output (million t/y) | 1 | 2 | 3 | 5 | |

| Roller breadth (mm) | 250 | 280 | 300 | 336 | |

| Roller diameter (mm) | 360 | 400 | 500 | 650 | |

| Power(kw) | 7.5 | 11-15 | 18.5-22 | 20-30 | |

| Speed of mainshaft (r/min) | 18 | 15 | 13 | 13 | |

| Reducer | ZQ350 | ZQ400 | ZQ500 | ZQ650 | |

| ZQ400 | ZQ500 | ZQ650 | ZQ750 | ||

| Pressure form | Oblique iron constant pressure | Oblique iron constant pressure | Oblique iron constant pressure | Oblique iron constant pressure | |

| Axle bed pull rod | Axle bed pull rod | Hydraulic type | Hydraulic type | ||

| Interchangeable of hydraulic and constant pressure | Interchangeable of hydraulic and constant pressure | ||||

| Roller texture | 65Mn | 65Mn | 65Mn | 65Mn | |

| 9cr2Mn | 9cr2Mn | ||||

| Alloy steel | Alloy steel | Alloy steel | Alloy steel | ||

| Structural style | Double-roller&single pressure type | Double-roller&single pressure type | Double-roller&single pressure type | Double-roller&single pressure type | |

| Four-roller&dual pressure type | Four-roller&dual pressure type | Four-roller&dual pressure type | Four-roller&dual pressure type | ||

| Mainshaft bearing | 319×4 | 319×4 | 2097724×4 | 2097724×4 | |

| Principal axis | φ95mm | φ110mm | φ135mm | φ165mm | |

| 45# steel | 45# steel | Forge piece | Forge piece | ||

| Spherical size | User defined | User defined | User defined | User defined | |

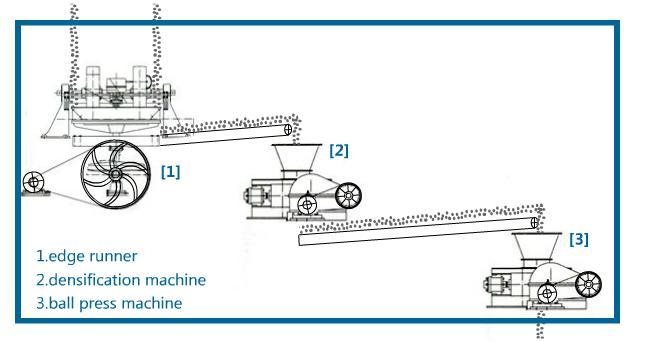

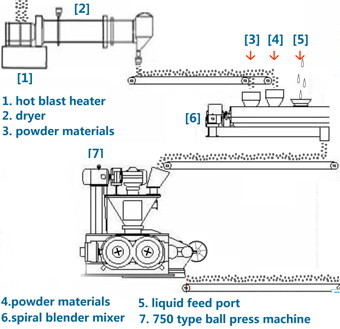

Briquetting Machine Production Line:

1.Briquetting machine is the equipment which presses the powder material into the briquette with different shapes.

2.Users can adjust the speed to achieve the highest briquett forming rate and maximum capacity according to the condition.The pressed materials are made into qualified briquettes and then are packed.Undersize materials can return to the storehouse and then be mixed with new materialto be pressed.

3.Strong structure,high briquetting ratio

Delivery

We have developed long and good relationship with many shipping agents. Ocean freight partners are: APL, COSCO, OOCL, CSCL, MSC, etc. and train shipping is also available. The perfect shipping way and best service with lowest price are always provided for customers.

Our Service Philosophy

1.Pre-sale services: enthusiasm

Provide you the prophase plan, process flow design and manufacturer equipment according to your special demand.

2.Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

3.After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.