HY aac block production line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 600 Set/Sets per Year |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

| Main Products: | Brick Making Machine, Aac Plant |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Brand Name: | HY |

| Production Capacity: | 600 Set/Sets per Year |

| Packing: | standard containers,or in bulks, bare main machines, motors and in wooden cases. |

| Delivery Date: | 25 working days after placing the order |

Product Description

Quick Details

Condition: New

Type: AAC Production Line

Brick Raw Material: Flyash,sand,pwoder sand,slag and other residue

Processing: Brick Production Line

Method: Hydraulic Pressure

Automatic: Yes

Capacity: 5-30 thousand M3/year

Place of Origin: Shanghai, China (Mainland)

Brand Name: HY

Model Number: JQF

Voltage: 380V

Power: None

Dimension(L*W*H): Depend customer's requirement

Certification: ISO9001:2000&CE

Warranty: one year

After-sales Service Provided: Engineers available to service machinery overseas

Guanrantee: One year

Experience: More than 20 years

Exported: More than 50 countries

Spare: Supply

Quality: World class

After-sale service: For whole using life

Maintenance: Easy and low cost

Training: Professional

Installation: Under our engineers guide

autoclave diameter: 2m or 2.68m

AAC block production line with good quality and competitive

1. AAC block production line Planning and design:

Factory covers an area of 6000~30000m2.(workshop at about 1800~3000m2)

Including raw material area, finished block area and production area.

Production flows includes raw material processing, rated material pouring, foaming, cutting and hardening procedure.

From foundation to equipments erection and testing, to trial producing, it will take 4-5 months.

2. AAC block production line Material:

1). Coal Flyash or Sand or Quartzite: Dry ash from power plant; sand from river side.

2). Cement: cement in bulk

3). Lime, gypsum and aluminum powder (buy at local area)

4). Water: from fresh supply water.

3. AAC block production line Water, electricity and steam supply:

1). Water supply: from well or use waste water

2). Electricity supply: install a 350~500KVA transformer

3). Steam supply: install a 4~8tons boiler to supply steam to autoclave and curing room

4. AAC block production line Product quality and specification:

We produce according to PRC standard GB11968-1997 "Aerated Autoclaved Concrete Block Technology".

1). Capacity category: 500, 600, 700kgs/ m3 (namely 3.5, 5.0, 7.5 Grade)

2). Compression strength level: 3.5, 5.0, 7.5Mpa (namely 3.5, 5.0, 7.5 Grade)

3). Drying shrinkage: less than 0.8mm/m

4). Thermal system: 0.11-0.22kcal/m.h.c

5). Sound insulation value: 47.45db

6). Frost resistance: 35.

7). Water absorbity :20.

8). Fire resistance: >4h, 200mm thinkness and up >8h.

5.AAC block production line Specification

Length: 600mm

Width: 100/ 125/ 150/ 200/ 250/ 300mm

Height: 150/ 200/ 250/ 300mm

6.AAC block production line Main technical parameters

a. Product density should be controlled around 650kgs/m3

b. Annual production capacity: 100,000~300,000 m3

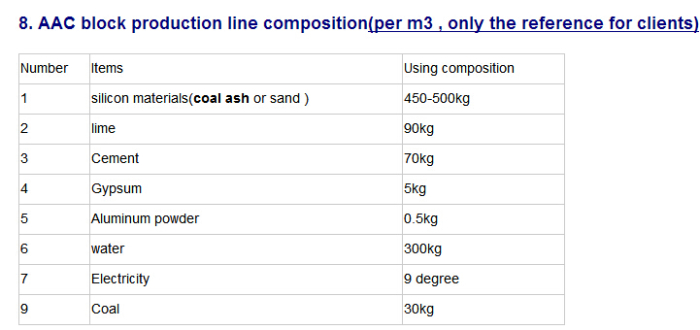

c. Material ratio: cement 5%, lime 15%, flyash 75%, gypsum 4-5%, aluminum powder 500g/m3

d. Water and material ratio: 0.63:1

e. 3.06m3/mould

f. Cutting period: 5-6 minutes

g. Curing time: 1.5-2.5 hours at 50-60°C

h. Autoclave: 6-8 hours(sand 10-12hours)

7. AAC block production line Main Advantage

1)Light weight

2)Good heat preservation

3)Good fire resistance without releasing harmful gas

4)Good workability

5)Good sound insulation.