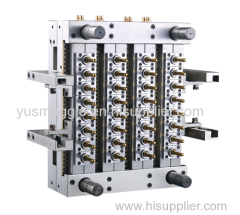

Fruit juices preform mold

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 500sets/year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | PET Preform Injection Mould/ Bottle Cap Mould/ PET High-speed Injection Machine |

Product Detail

| Model No.: | YUS-106 |

|---|---|

| Means of Transport: | Ocean |

| Product: | Others |

| Product Material: | Plastic |

| Shaping Mode: | Plastic Injection Mould |

| Brand Name: | YUS |

| Production Capacity: | 500sets/year |

| Packing: | Wooden case |

| Delivery Date: | 45days |

Product Description

cosmetic pet bottles preform mold

Name Description

Name | Description |

Mould material | S136,2316 etc. |

Mould base | 45#, P20, 3Cr13, |

Cavity | Single/multi |

Runner | Hot |

Design software | PROE, CAD,CAE,CAM etc. |

Plastic material | PP,PE,PET etc. |

Mould life | 500,000-3,000,000 shots/cav |

Delivery time | 30-50days |

Specification | Depends on customer's requirements. |

Step

1.R&D | We support customer R&D. Make the files or improve the design if you needed. |

2.Negotiation | the quality, price, material, delivery time, payment item, ect. |

3.Place an order | according your own design or you chooses our design. |

4. Mould | According customers request to build the mould. Before make the mould, we send mould design to customer approval first, before move forward to production; we send samples to customer to confirm first. |

5. Sample shoot | If the first sample come out is not satisfied customer, we modify the mould and until meet customers satisfactory. |

6.Products in store | If your quantity is beyond our storage, we will provide lead time to you. |

7. Delivery | Delivery goods by sea or by air, according customers requirement. |

1.SERVICE

1) More than 20 years experience in PET Preform Mould

2) Devote to professional packaging solutions for beverage,medicine,daily commodity,plastic cosmetics.

2.MOULD FEATURES

1) Core,Cavity and Neck can be interchanged. We have advanced heat treatment equipment,which assures the hardness ofmould components (S136 steel 50-52HRC,P20 Steel 35-38HRC).And the OPs have abundant professional experience and strict working flows.

2) Excellent hot runner system and cooling system.

3) High quality materials and proven mold design ensure long life time.

4) Pneumatic Pin Valve strcuture without manual cut tail,reduce the labor force.

5) Double self-lock structure ensures mold thickness tolerance less than 0.05mm

1) Less energy cost and pressure lost

2) Use imported heaters,like Germany HOTSET .

3) Cavity-to-cavity control system ensure nozzle temperature fluctuates within 1oC

4) Hot Runner Balance design ensures evenly force,uniform heating and identical preforms.

4.COOLING SYSTEM

1) Sprial Water Cooling Way on cavity enhances cooling performance.

2) Cooling System on neck and move neck plates enhance cooling performance.

3) Precise Distributary Plate distributes cooling water into cavity evenly, quicken perform cooling.