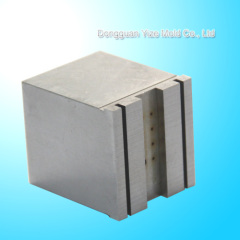

JAE custom precision connector mold parts

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10000pcs/month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

Product Detail

| Model No.: | Non-standard |

|---|---|

| Means of Transport: | Ocean, Air |

| Product: | Vehicle Mould |

| Product Material: | Metal |

| Shaping Mode: | Plastic Injection Mould |

| Brand Name: | yize |

| Place of Origin:: | Guangdong, China (Mainland) |

| Size:: | customized |

| Gemeral precision:: | 0.005mm |

| Grinding precision:: | 0.001mm |

| Grinding anlge clearness:: | 0.002mm |

| MOQ:: | 1 piece |

| Production Capacity: | 10000pcs/month |

| Packing: | Paper of Box |

| Delivery Date: | 10days |

Product Description

JAE custom precision connector mold parts

connector mold parts

The actual manufacturing connector mold parts process, several intertwined, need to connector mold parts design and mold master schedule each link, one step wrong, full basin are negative! Rework is often caused by the mold damage, do out of connector mold parts is not pretty. To remedy the good words, only refueling, this will increase the time and cost, and a lot of time is the most important. connector mold parts industry competition is intense now, customers give mode real time is urgent, not to die, will eventually lose customers! The function of each processing machinery and equipment, gongs bed, work for the artificial milling, cutting rules are relatively simple shapes,, such as line, slash; used to machining accuracy is not very high in the workpiece, mold opening frame, mold, for a material etc.. 2, lathe, mainly used for machining circular, such as sprue, positioning ring, flange, circular die Oh (CORE), round copper public; precision can reach higher requirements. 3, grinding machine, mainly used for steel grinding, grinding datum, which can meet the high precision requirement.drilling machine, mainly used for drilling, tapping, a hole transport. CNC (computer gongs), has become a symbol of the modernization of equipment mould industry, mainly used for numerical control machining of complex, irregular surface. The characteristics of high precision, good reliability, high efficiency, processing any mould basically all cannot do without it. Processing of cavity, copper, and other parts of the workpiece can be processed; it almost any shape.

Product Information

| Product name | connector mold parts |

| Material | imported material:SKD11,SKH9,SKH51,SKH55,high-speed steel,special material can customize |

| Size | custom |

| Grinding precision | 0.001mm |

| Surface roughness for EDM | Ra 0.04 |

| EDM precision | 0.002mm |

| Grinding angle clearness | 0.002mm |

| MOQ | 1 PC |

| QC report | include |

| Delivery type | DHL express |

| Delivery time | 10 days |

| Packaging type | paper of box |

| payment term | T/T,30% deposit,70% balance after receiving parts |

Production Information

| Product accuracy | diamension tolerance ±0.001mm ,axiality within 0.002mm,roundness withing 0.0015mm,surfacae roughness wthin Ra 0.025,straightness within 0.002 |

| Technique standard | according to national standars GM,JIS,DIN,AISI,ect. and other national standard |

| Technique advantage | grinding parts with precision less than 0.002,precise EDM parts with precision less than 0.005 |

| Production equipment | all machinery used from import ,with EDM 15 sets,grinder 15 sets,,wire-cutting 3 sets,CNC 2 sets,milling machine 1 set |

| Our service | grinding process,grinding surface process,electro-discharge(wire EDM),CNC EDM,mirror EDM,CNC processing,precision mold parts process |

Yize team is here to serve your!

Welcome to figure offer, the price is for reference only, we have a professional considerate service to you.

zjxinniu520 recommend you connector mold parts

Contact Yize Mould

Dongguan YIZE MOULD Co.,LTD

connector mold parts Address: Hexing Road No.122, South Shatou District, Chang'an Town, Dongguan City, Guangdong Province

connector mold parts TEL: 0769-81888 522

connector mold parts FAX: 0769-81888 548

connector mold parts Website: www.yizemoulds.com

connector mold parts E-mail: Jack@dgyize.com