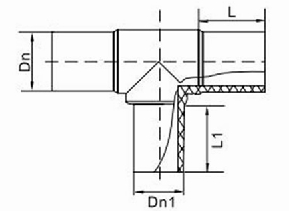

hdpe butt fusion injection equal tee pipe fittings

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50000pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Pp Reducing Coupling Pipe Fittings Wth Pn16, Pp Female Threaded Coupling Compression Fittings, High Quality Pp Reducing Tee Pipe Fittings, High Quality Injection Pp Coupling Fittings, High Pressure Pp Equal Tee Pipe Fittings With Pn16 |

Product Detail

| Model No.: | aer1006 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Head Code: | Others |

| Shape: | Equal |

| Technics: | Others |

| Type: | Tee |

| Material: | Plastic |

| Connection: | Others |

| Brand Name: | aer |

| Material: | HDPE80 or HDPE100 |

| Working Pressure: | SDR11,SDR13.6,SDR17 |

| Surface Color: | Black |

| Process: | Injection |

| Means of transport: | Ocean, air |

| Packing: | Cartons or bags |

| MOQ: | 10 cartons per size |

| Delivery Time: | Within 45 days |

| Payment Terms: | T/T, L/C at sight |

| Export Area: | All over the world |

| Production Capacity: | 50000pcs/month |

| Packing: | cartons |

| Delivery Date: | 45 days |

Product Description

hdpe butt fusion injection equal tee pipe fittings

***Comparison between PE pipe fittings and other piping, Our PE pipe fittings have

the following advantage:

1). Economical efficiency: Low comprehensive fabrication cost, long service life is over 50 years.

2). Corrosion resistance: Anti-corrosion in seawater and alkali soil, no galvanic corrosion.

3). Sanitation: Colorless and tasteless, harmless to human body.

4). Impact resistance: Good impact resistance performance

5). Flexible: Suitable for all topography, non-brake when earthquake and subsidence because of

non-equilibrium section of land.

***Specifications:

Code No.: aer1006 | |||

Pressure Grade: SDR11,SDR13.6,SDR17 | |||

| |||

SIZE | SIZE | SIZE | SIZE |

DN40 | DN125 | DN250 | DN500 |

DN50 | DN140 | DN280 | DN560 |

DN63 | DN160 | DN315 | DN630 |

DN75 | DN180 | DN355 | DN800 |

DN90 | DN200 | DN400 | DN1000 |

DN110 | DN225 | DN450 | DN1200 |

***Basic performance of raw materials for pipe fittings

| Paramenter | Units | Requirement | Test Value |

| Density | kg/m³ | ≥930 | 23ºC |

| Melt flow rate | g/10min | 0.2~1.4 | 190ºC,5kg |

| Thermal slaility (OIT) | min | >20 | 200ºC |

| Volati lematter content | mg/kg | ≤350 | |

| Moisture content | mg/kg | ≤300 | ASTM D 4019:1994a |

| Carbon black content | % | 2.0~2.5 | |

| Crbon black dispersion | grade | ≤3 | |

| Gas proof components | h | ≥20 | 80ºC,2MPa(Hoop stress) |

Resistance to slow crack growth (En>5mm) | h | 165 | 80ºC,0.80MPa(Testing pressure) 80ºC,0.92MPa(Testing pressure) |