Plastic WLDH Ribbon Mixer

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 3 sets per month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Other |

| Main Products: | Plastic Recycling Machine , Plastic Pelletizing Machine, Plastic Extrusion Machine , Plastic Auxiliary Machine |

Product Detail

| Model No.: | NSD |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Plastic Type: | Others |

| Use: | Others |

| Shaft Design: | Others |

| Brand Name: | NEWSTAR |

| Power: | 5.5-75kw |

| Capacity: | 150-1200kg/h |

| Name: | WLDH Ribbon Mixer |

| Production Capacity: | 3 sets per month |

| Packing: | film with wooden case |

| Delivery Date: | 30 days |

Product Description

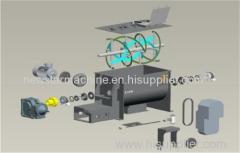

WLDH Ribbon Mixer

Description:

The plastic mixer horizontal axes make the materials move up and down.The outer ribbon gathering the material from sides to center and the inner ribbon pushing the material from center to sides.Every screw makes the materials do axial and radial movement, the materials do relative cyclical movement so to gain the uniform mixing.There is a discharging valve at the bottom of the body/container. When mixing different types of materials, we use flat discharging valve.

The plastic mixer operation of the discharging valve should be convenient and there are three types: manual, air driven and electricity driven.The manual discharging is operated on the valve and the open extent is controlled by hand freely.The air driven discharging valve, assembled with cylinder, work under the air pressure.

The electricity driven discharging valve works under control of electricity control box.

Applications:

WLDH series cubic ribbon plastic mixer,mainly used in coloring plastic particals,mixing,etc,is the injection molding machine,extrusion machine is one of essential equipments.

Specifications:

Model WLDH | 500 | 2000 | 4000 | 6000 | 8000 | 10000 | 15000 | 20000 | ||||

Dimension(Length*width*height)mm | 2670×780×1240 | 3860×1200×1650 | 4950×1400×2000 | 5530×1560×2200 | 5100×1720×2500 | 5610×1750×2650 | 7100×2200×3350 | 7560×2360×3550 | ||||

Load Factor | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | ||||

Discharging mode | valve | valve | pneumatic | pneumatic | valve | valve | pneumatic | pneumatic | ||||

Rotating Speed (rpm) | 41 | 33 | 8-24 | 27 | 22-80 | 22 | 22 | 22 | ||||

Output(kg)P=1g/cm3 | 150-250 | 800-1200 | 2000 | 2000-3000 | 3000-4000 | 4000-6000 | 7500-9000 | 8000-12000 | ||||

Motor Power (kw) | 5.5 | 18.5 | 22-37 | 37 | 45 | 45-75 | 75 | 75 | ||||

Mixing time(min) | 10-30 | |||||||||||

Weight (kg) | 900 | 2700 | 4200 | 5600 | 6500 | 7800 | 13000 | 15000 | ||||

Competitive Advantage:

1.Adopting advanced design,be operated easily

2.Safely and reliably.

3.Temperature control

4.High efficiency,low energy consumpation

5.Low noise