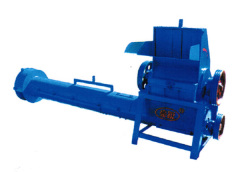

PET Plastic Bottle Crusher

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 3 sets per month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Other |

| Main Products: | Plastic Recycling Machine , Plastic Pelletizing Machine, Plastic Extrusion Machine , Plastic Auxiliary Machine |

Product Detail

| Model No.: | NSD |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Plastic Type: | PET |

| Use: | Bottle Crusher |

| Shaft Design: | Others |

| Brand Name: | NEWSTAR |

| Power: | 15-75kw |

| Capacity: | 100-1500kg/h |

| Name: | Plastic Bottle Crusher |

| Production Capacity: | 3 sets per month |

| Packing: | film with wooden case |

| Delivery Date: | 30 days |

Product Description

Plastic Bottle Crusher

Description:

PET washing line plastic bottle crusher's blade is made of high-quality tool steel, is very durable, and can adjust flexibly blade's installment. Blade can use many times. Material falling hopper, machine station adopt separate design, filter screen, base all assemble as norm hole, is easy to clear, and this machine has clear chamber and protection of blade adjusting to confirm the safety when clearing and adjusting. Motor has overload protection, protect system together with power to ensure safety.

1) Strong structure, easy to operate, low electricity consumption & durable.

2) Uses high quality steel material especially for making knives of the crushers, the machine stands long use under severe and continuous service conditions.

3) The blades can be grinded for many times and can be used repeatedly

4) Blades base is made of T10 high quality steel, hard to be broken and damaged; Blades base structure is stable and durable

5) With flat type, claw type and cross type blade and screen with different hole size for chose to suit various demand.

6) With double reduce noise layer design to reduce noise output.

7) Has protection system with the power supply to ensure the equipment safe

8) Easy to clean and maintain, the hopper, crusher room, blades and screen can be removed and mounted easily.

9) Necessary for the plastic extrusion machines and other plastic recycling industry.

Applications:

PET washing line plastic bottle crusher absorbs advanced technology from abroad, improves continually, and makes this machine as advanced, new plastic machine all over the world. This machine has ten series and thirty types, can resolve all waste plastic crushing, and also have special crusher to crush the hard material(ABS,PS,PA and etc), soft material(PVC,PU and etc), pipe(PE,PP-R and etc), bottle(PET and etc), film(PP,PPO and etc) and other different material. Crusher has good report in the crusher manufacturer filed at the part of high efficiency, power-saving, durability.

1. PET bottle, drink bottle label, bottle cap,

2. PE film, agricultural film, bag, PE pipe, water pipe, drainage pipe,

3. PP woven bag, PP water drum, PP cup, PP film, sheet, pallet, basket

4. LDPE/HDPE film, sheet, flake, lump, board,

5. PVC pipe, profile, window frame, door frame, soft PVC door curtain

6. Wood plastic window/door,

7. PC/ABS water drum, LOCK and LOCK crisper,

8. Rubber tyre, rubber/plastic material from injection mold,

9. TV shell, keyboard, mouse, TV remote controller, toys, torch, plastic helmet, file folder, brochure shelf, canvas, coat hanger, bumper bar, gas tank

10. fiber, coconut fiber, jute fiber

11. nylon

12. non-woven fabric

13. leather, artificial leather, leather shoes, leather clothes, leather hand bags

Specifications:

Model | PSJ600 | PSJ800 | PSJ1000 | PSJ1200 | PSJ1500 |

Power(kw) | 15 | 30/37 | 37/45 | 55 | 75 |

Qty of rotary blade | 6 | 6 | 6/10 | 10 | 10 |

Qty of fixed blade | 4 | 4 | 4 | 4 | 4 |

Capacity(kg/h) | 100-300 | 200-500 | 400-800 | 800-1100 | 1000-1500 |

Net diameter(mm) | 8-12 | 10-18 | 10-18 | 10-18 | 10-18 |

Size of material input(mm) | 600*340 | 800*500 | 1000*600 | 1200*710 | 1500*800 |