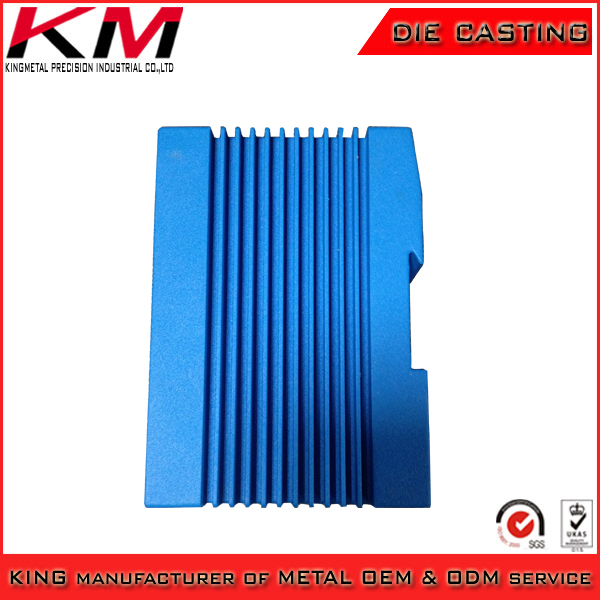

A360 casting sandblasted waterproof communication enclosure case

| Min. Order: | 50 Piece/Pieces |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 12,000 pieces / Month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | OEM And ODM Die Casting, CNC Machining, Aluminum Extrusion And Stamping |

Product Detail

| Model No.: | KM-DC-3869 |

|---|---|

| Means of Transport: | Express, Ocean, Air, Land |

| Brand Name: | KingMetal |

| Item: | Casting communication enclosure case |

| Machininng: | Casting |

| Material: | Aluminium alloy & zinc alloy |

| Surface finish: | Powder coated,painting,plating,etc. |

| Type: | Casting case |

| Secondary machining: | Drilling,milling,deburring,cnc machining,welding,bending,etc. |

| Price terms: | EXW,CIF,FOB,etc. |

| Other service: | CNC machining,aluminum extrusion and stamping |

| Application: | Casting comminication case |

| Certificate: | SGS, ISO14001:2004, ISO9001, RoHs |

| Production Capacity: | 12,000 pieces / Month |

| Packing: | Bubble bag + Carton box + Wooden pallet or as per customers' request. |

| Delivery Date: | 8 - 15 working days |

Product Description

By working closely with our clients, we help them to optimize their designs to provide the best in:

Cost

Feature Integration (usually resulting in reduced cost and weight and improving quality)

Near Net Shape

Heat Dispersion

Corrosion Resistance

Strength & Durability (through alloy selection and optimized part design)

Quality (consistency, dimensional accuracy, surface finish and etc.)

Machining feature:

High pressure casted is a metal casting process that is characterized by forcing molten metal under high pressure into a mould cavity. Our aluminum die casting cover have the advantages:

Lightweight, high precision dimensional stability for complex shapes and thin walls

Good corrosion resistance; good mechanical properties

High thermal and electrical conductivity

Retains strength at high temperatures

More specification about high pressure casted:

| Machining | Aluminum die casting/High pressure casted/aluminium alloy die casting/die casted |

| Item | High pressure die casted aluminium alloy machinery fitting parts |

| Material | Aluminum alloy:A356,A360,ADC10,ADC12,etc. Zamak alloy:Zinc 3#,Zinc 5#,etc. |

| Secondary machining | Welding,bending,cutting,milling,drilling,turning,etc. |

| Surface treatment | Powder coated,painting,plating,pearl chrome,brushed,teflon,etc. |

| Main market | The United States,Germany,Norway,Canada,Brazil,Russia,France,The United Kingdom,Pakistan,Thailand,Ghana,Netherland,Norway,etc. |

| Main service | Aluminum die casting,zamak/zinc die casting,cnc machining,aluminum extrusion and stamping. |

| Note | All our products are customized,no stock. |

Sample shows:

Packaging:

Shipping & Payment:

---Express globally: DHL, UPS, FEDEX, TNT, EMS,etc.

---Shipping Sea & Air Port: Shen Zhen,Guang Zhou,Hong Kong,etc.

---Payment: L/C, T/T, D/A, D/P, Western Union, MoneyGram,Paypal.

Contacts:

This is Sandy from KingMetal,thanks a lot for your patient reading.

Please kindly contact us for more information.

KingMetal Precision Industrial Co.,Ltd.

Sandy W Cheung -- Oversea Sales Dept.

E-mail:sales3@szkingmetal.com

Skype:sales3-kingmetal

Whatsapp & Cel:+86 13531671350

Tel:+86 755 84111279

Fax:+86 755 28693879

Add:Yan Yang Industrial Zone,LongTeng Road,KengZi Town,

Shenzhen City,Guangdong Province,China.