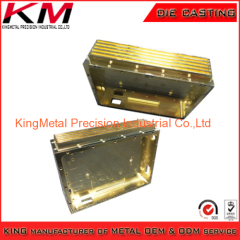

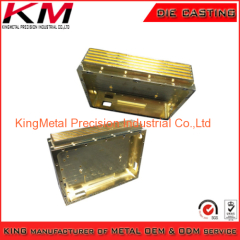

High pressure die casted plating aluminium alloy machinery heat sink parts

| Min. Order: | 50 Piece/Pieces |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 8,000 pieces |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | OEM And ODM Die Casting, CNC Machining, Aluminum Extrusion And Stamping |

Product Detail

| Model No.: | KM-DC-38694 |

|---|---|

| Means of Transport: | Express, Ocean, Air, Land |

| Brand Name: | KingMetal |

| Item: | Aluminium alloy die casted heat sink parts |

| Machining: | High pressure die casted |

| Material: | Aluminium alloy & zinc alloy |

| Secondary machining: | Drilling,milling,cutting,etc. |

| Type: | Aluminium alloy heat sink |

| Surface finish: | Plating,painting,powder coated,etc. |

| Tolerance: | +/-0.5mm |

| Our service: | OEM and ODM |

| Application: | Aluminium alloy heat sink |

| Certificate: | SGS, ISO14001:2004, ISO9001, RoHS. |

| Production Capacity: | 8,000 pieces |

| Packing: | Bubble bag + Carton box + Wooden pallet or as per customers' request. |

| Delivery Date: | 8 - 15 working days |

Product Description

Our die casting feature:

As the aluminum die casting parts designer, manufacturer, supplier in China, Our aluminum part manufactory have more than 8 years experience with aluminum die casting, sells the aluminum die casting products all over the world. Our aluminum die casting parts include aluminum die casting gear housing, aluminum die casting case, aluminum die casting frame, aluminum die casting cover, aluminum die casting cylinder body, aluminum die casting led housing, aluminum die casting radiator, custom aluminum die casting part, aluminum die casting adaptors and connectors, aluminum die casting box, aluminum die casting light parts, aluminum die casting auto parts,etc.

More information about KingMetal:

KingMetal Precision Industrial Co., Ltd. is the professional manufacturer and exporter of the OEM and ODM metal products in Shenzhen, China. Mainly offers technical supports including: Die Casting, CNC Machining, Aluminum Extrusion and Stamping.

Founded in Hong Kong in 2004, then expanded the manufacturing plant in 2005.At present, KingMetal covers a scale of more than 3000 square meters and has hundreds of professional employees working in our various departments.

We strictly require and control the quality to ensure it is qualified before delivery. Good quality and reasonable price are always will be important in every business.

In our trade with merchants of various countries, KingMetal always adhere to the principle of equality and mutual benefit. It is our hope to establish, by joint efforts, trade relationship with you.

Machining feature:

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mould cavity. Our aluminum die casting cover have the advantages:

Lightweight, high precision dimensional stability for complex shapes and thin walls

Good corrosion resistance; good mechanical properties

High thermal and electrical conductivity

Retains strength at high temperatures

More specification about die casting:

| Machining | Aluminum die casting/aluminium alloy die casting/die casted/die cast |

| Item | Part used die casting machine |

| Material | Aluminum alloy:A356,A360,ADC10,ADC12,etc. Zamak alloy:Zinc 3#,Zinc 5#,etc. |

| Secondary machining | Welding,bending,cutting,milling,drilling,turning,etc. |

| Surface treatment | Powder coated,painting,plating,pearl chrome,brushed,teflon,etc. |

| Main market | The United States,Germany,Norway,Canada,Brazil,Russia,France,The United Kingdom,Pakistan,Thailand,Ghana,Netherland,Norway,etc. |

| Main service | Aluminum die casting,zamak/zinc die casting,cnc machining,aluminum extrusion and stamping. |

| Note | All our products are customized,no stock. |

Our capacity

| The technologies be offered: | 2 Zamak Die Casting 3 CNC Machining 4 Extrusion/Profile 5 Stamping |

| The surface finish be provided: | 1 Powder Coated 2 Oxidation 3 Sand Blast 4 Painting 5 Brush 6 Teflon 7 Etc. |

| Other services be supplied: | 1 OEM / ODM service 2 Twenty-four hours on-line service 3 Professional technologies and staff 4 All kinds of certification can be offered 5 Address client concerns 6 Sample can be offered 7 Etc. |

Sample shows:

RFQ:

Q:What kinds of information you need?

A:Please kindly send us your drawing(2D and 3D drawing is the best),material and surface finish request for quotation.

Q:How long you need to quote?

A:In Monday to Friday,our quotation could be offered within 18 hours and the quotation in weekend will be offered in next Monday.

Warmly welcome to our factory and talk face to face.

Packaging:Bubble bag + Carton box + Wooden pallet or as per customers' request.

The Shipping & payment:

Shipping:--By sea,air or DHL,TNT,UPS,EMS,Fedex,etc.

Payment:--By T/T,L/C,D/P,D/A,MoneyGram,Western Union,Paypal.

KingMetal Precision Industrial Co.,Ltd.

Sandy W Cheung -- Oversea Sales Dept.

E-mail:sales3@szkingmetal.com

Skype:sales3-kingmetal

Whatsapp & Cel:+86 13531671350

Tel:+86 755 84111279

Fax:+86 755 28693879

Add:Yan Yang Industrial Zone,LongTeng Road,KengZi Town,

Shenzhen City,Guangdong Province,China.