China Leading Mining Equipment Raw Material Mill

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU, MoneyGram |

| Supply Ability: | 4.5-210t/h |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Heavy Mining Machinery And Civilian Machinery |

Product Detail

| Model No.: | Fote Raw Mill |

|---|---|

| Means of Transport: | Ocean |

| Condition: | New |

| Brand Name: | Fote |

| Power(W): | 245kw |

| Certification: | BV,CE,GOST,ISO9001:2008 |

| Production Capacit: | 6.5-135 TPH |

| Model Number: | 1.83*7---4.6*14 |

| Application: | cement,various ores,etc |

| Speed reduction ratio: | 4.5-35.5 |

| Voltage: | 380v |

| Weight: | 43.8-485 t,4.6-137 t |

| Production Capacity: | 4.5-210t/h |

| Packing: | standard container,spare parts will be packed in wooden cases |

| Delivery Date: | Within 5-25 working days after placing the order |

Product Description

Introduction of China Leading Mining Equipment Raw Material Mill

Raw material mill is one of the major cement equipments and is the key equipment for grinding materials after being broken, so it is widely used in dry or wet grinding process of all kinds of ores and other materials in industries of cement, silicate, new building material, refractory material, fertilizer, black and non-ferrous metal and glass ceramics.

Advantages of China Leading Mining Equipment Raw Material Mill

1. Raw material mill drive is in the form of edge-transmission. The compact structure saves space, thus saving customers` investment.

2. Its structure reduces ventilation resistance, enlarges the effective volume, increases mill`s output;

3. The design structure of the lining board significantly improves grinding efficiency and effectively prevents powder leakage phenomenon from occurring.

Fote Machinery is China`s well-known raw material grinding mill manufacturer and raw material grinding mill supplier. In addition, the raw material mill price is quite reasonable. If you would like to know about our products or have any question, please do leave us a message, we will respond you as soon as possible. Thank you.

Features of China Leading Mining Equipment Raw Material Mill

The raw material mills feature strong adaptability of materials, continuous production, high reduction rate, simple adjustment of the powder fineness. This mill can work with the drying equipment at the same time through the wet or dry process.

Working principle of China Leading Mining Equipment Raw Material Mill

The raw material mill adopts the edge transmission model. After materials are transported into the raw material mill continuously via the feeder, the motor drives the mill cylinder to rotate through the reducer. Materials are conveyed to the first cabin in a spiral way along the hollow shaft and the steel balls and the materials inside the mill are turned over by the cylinder in the effect of friction and centrifugal force. When materials are lifted to certain height, they are scattered down like a material curtain and then are impacted by the steel balls. The qualified crushed products are discharged out of the mill and are separated by the separation equipment. The unqualified materials in the circulating system will return to the mill for further impacting and grinding processes until reaching the required fineness.

Parameter

| Product specification (m) | Milling form | Transmission form | Gear box | Motor power (kw) | Production capacity (t/h) | Total weight (t) | |

| Model | Speed reduction ratio | ||||||

| Φ1.5×5.7 | Open flow | Brim | ZD40 | 3.55 | 130 | 4.5-6 | 25.8 |

| Φ1.83×6.4 | Open flow | Brim | ZD60 | 4.5 | 210 | 7.5-15 | 43 |

| Φ2.2×6.5 | Circle flow | Brim | ZD70 | 5 | 380 | 14-26 | 60 |

| Φ2.4×7 | Circle flow | Brim | ZD70 | 5 | 475 | 24-28 | 81 |

| Φ2.4×10 | Circle flow | Brim | ZD80-4-Ⅱ | 6.435 | 570 | 32-36 | 118 |

| Φ2.6×10 | Circle flow | Brim | JDX710 | 6.3 | 800 | 45-50 | 130 |

| Φ3×9 | Open flow | Brim | JDX800 | 6.3 | 1000 | 55-60 | 158 |

| Φ3.2×9 | Circle flow | Brim | MBY900 | 7.1 | 1250 | 62-65 | 195 |

| Φ3.5×10 | Open flow | Brim | JDX900 | 5.84 | 1250 | 70-75 | 200 |

| Φ3.8×7.5 | Circle flow | Brim | JDX900 | 5.6 | 1600 | 80 | 233 |

| Φ4.6×10+3.5 | Circle flow | Central shaft | JQS3550 | 15.1 | 3550 | 190 | 415 |

| Φ4.6×10.5+3.5 | Circle flow | Central shaft | JQS3550 | 15.1 | 3550 | 210 | 476 |

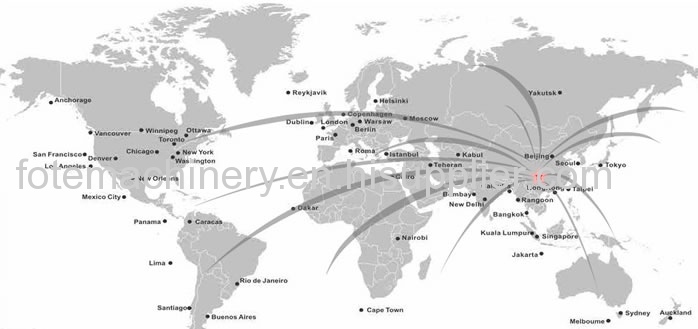

Sales Network

Our company always carries out the customer service principle that 'implement service and operation with customers needs as the center and practice brand service with customer satisfaction as the goal', and runs the service spirit of 'enthusiasm before sales, servant in sales and faithfulness after sales' through the whole sales network.

Official Website: http://www.fote-machine.com/product/raw-material-mill.html

http://www.china-ftm.com/pros/raw_material_mill.html