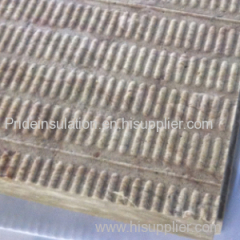

High strength Rock wool board

| Min. Order: | 5 Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 150 tons per day |

| Place of Origin: | Shandong |

Company Profile

| Location: | United States |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Thermal Insulation Ceramic Fiber Board, Thermal Insulation Ceramic Fiber Textiles, Ceramic Fiber Insulation Paper, Ceramic Fiber Insulation Blanket, Fiberglass Needle Mat E Type |

Product Detail

| Model No.: | PD-RWB-01 |

|---|---|

| Means of Transport: | Ocean, Land |

| Material: | Others |

| Brand Name: | PRIDE |

| Apparent Density: | 60-200 |

| Heat Conductivity: | Max 0.039W/(m.k) |

| Highest Working Temperature: | 650C |

| Thickness: | 30-200mm |

| Production Capacity: | 150 tons per day |

| Packing: | heat shrinking film |

| Delivery Date: | 7days after a firm order |

Product Description

Puruide rock wool board is made of select fine basalt as the major materials which is pulled into 4‐7µ non‐continuous fibers after melted by adopting advanced international four roller centrifugal cotton‐making procedures and adding a certain of adhesives, dust laying oil and water repellent into rock wool fibers. It can be made into products series with different density according to various uses through the technology of sedimentation, solidify, cutting and etc.

Application:

Petrochemical industry-- heat insulation and sound absorption of equipments for petroleum industry, power industry and chemical industry.

Construction industry-- building's exterior wall, partition wall, curtain wall, roof and building envelope thermal insulation and acoustic noise reduction.

Mining industry-- heat preservation and fireproof for industrial kiln, oven, large storage tank and shipping.

Technical Data:

Shot content (particle diameter ≥ 0.25mm), % | ≤ 10.0 |

Average fiber diameter, μm | ≤ 7.0 |

Density tolerance, % | +10, -10 |

Thermal conductivity coefficient (average temperature: 70±52), W/(m. K) | ≤ 0.039 |

Thermal load contraction temperature (products with density above 60kg/m3), | ≥ 720 |

Moisture content, % | ≤0.2 |

Combustion property | Non-combustible |

Organic material content, % | ≤ 3.0 |

Water repellence(water-proof),% |

≥98

|

Water absorption(water-proof),% |

≤5

|

Compressive strength (With 10% deformation) , KPa |

≥40 |

Delamination strength, KPa |

≥7.5

|