Superior Quality Stone Crushing Production Plant

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 sets/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Mining Machinery Block Machine |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Application: | Ore |

| Type: | Others |

| Brand Name: | CACTUS |

| Condition: | New |

| Application: | Quarry and Mining Road Construction Building |

| Motor Type: | AC Motor |

| Capacity: | 80-500TPH |

| Certification: | ISO9001:2008/CE |

| Warranty: | for one year |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Operation:: | Operation: our engineers available for you |

| Installment:: | under our engineers' guidance |

| Production Capacity: | 50 sets/month |

| Packing: | Standard Export Package |

| Delivery Date: | 60 working days after receiving downpayment |

Product Description

Superior Quality Stone Crushing Production Plant

Brief introduction

Stone making production line is a special equipment to produce building stone. The stone, produced by this line, is particle size equally, high compressive strength, which is more satisfied to use in building than natural sand.

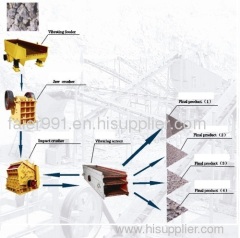

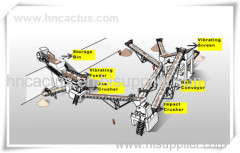

Working principle

First the raw materials are regularly conveyed into the elementary-crushing machine by the vibrating feeder, then the belt conveyor transfers the elementary products to impact crusher for secondary crush.

The secondary products will be separated into stone of different sizes by the vibrating screen. The parts not satisfying the needs will be returned to the impact crusher for further crush.

The design of Stone Crushing machine/crusher plant is usually decided by several factors:

1) raw materials to be crushed

2) The hardness, percentage of Si, moisture percentage of the raw materials

3) The average size of the raw materials before entering into the crushing system

4) Requested product sizes, percentage of the sizes, and their usage

5) hour capacity of the crushing line

Main equipments

The main equipments of stone making production line including the stock bin—vibrating feeder—jaw crusher—impact crusher—vibrating screen—final stone material, those equipments are connected by belt conveyor.

During processing, the equipment can send various materials into the crushers in the given time, separating the raw materials primarily. It is widely used in metallurgy, coal ore, construction materials, etc.

2) PE-Jaw Crusher

PE-series of jaw crusher is widely used at home and aboard, for primary crushing of hard rocks and block materials. The large and medium-size crushers are the key products of our company and stand in the front of the industry in the aspect of design and production.

3) Impact Crusher

Impact Crusher Machine is a new product designed by our company after absorbing the advanced technology at home and abroad. Our impact crusher machine production function to deal with side length of not more than 500 mm, not more than 350Mpa compressive strength of the various coarse, medium and fine material (granite, limestone, concrete, etc).

4) Vibrating Screen

This series of vibrating screen moves round, it is specially designed for quarry to separate stone into different sizes. It also widely used for classification in mining, construction materials, transportation and energy etc.

Proposals:

We warmly welcome you to come to inspect our factory, and we would like to design the most suitable proposal as per your requests. The following proposals are for your reference.

Raw material | Capacity | Feeder | Primary crusher | Secondary crusher | Screen |

Stone/iron ore | 30-50 | GZD300*90 | PE400*600 | PF1010 | 3YK1237 |

Stone/iron ore | 50-80 | ZSW380*96 | PE500*750 | PF1210 | 3YK1548 |

Stone/iron ore | 80-120 | ZSW380*96 | PE600*900 | PF1214 | 3YK1860 |

Stone/iron ore | 120-200 | ZSW490*110 | PE750*1060 | 2*PF1214 | 3YK2160 |

Stone/iron ore | 200-300 | ZSW590*110 | PE1000*1200 | 2*PF1315 | 3YK2460 |

Stone/iron ore | 300-400 | ZSW590*110 | PE1000*1200 | 2*PF1315+2*PF1214 | 2*3YK2460 |

Stone/iron ore | 400-500 | ZSW590*110 | PE1200*1500 | 2*PF1315+2*PF1315 | 2*3YK2460 |