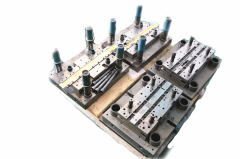

High quality precision stamping die

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Supply Ability: | 800/year |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Stamping Die, Metal Stamping Parts, Connnector Terminal |

Product Detail

| Model No.: | OEM |

|---|---|

| Product: | Vehicle Mould |

| Product Material: | Metal |

| Shaping Mode: | Punching Mold |

| Brand Name: | Heju |

| OEM/ODM: | Yes |

| Tooling Life: | 300 Million Times |

| Production Capacity: | 800/year |

| Packing: | In plastic box,carton or according to customer's requirements. |

| Delivery Date: | Shipped in 25 days after payment |

Product Description

Product description

Advantage:

1.The product uses the high quality metal plate,

2.Strict control of product size,

3.Products through the TS16949 certification,

4.Shrapnel product life of up to 300 million times,

5.Terminal products will not be high current breakdown,

6.Easy to assemble to consumer electronics,

7.Provide mold maintenance services,

8.Product unit price is reasonable,

9.Salt fog test after 72 hours.

Product service

OEM/ODM:

1.Customers provide product drawings, we design mold proofing, in line with customer requirements.

2.Customers provide product samples, we design mold proofing, in line with customer requirements.

3.The customer puts forward the product requirements, we design the product style, make mold proofing, meet customer requirements.

Logistics information

Can express delivery service, we are responsible for shipping.

Related products recommended

We also sell stamping die, provide mold design and mold repair services, professional custom products to meet customer requirements

.

Brand Name: Heju

OEM/ODM: Yes

Min Pitch: 0.4mm

Plating: Accepted

Material: Metal

Stamping Speed: 60-1000SPM/min

Material Thickness: 0.05-2.0mm

Surface: No scratches

Size: Customized

Certificate: ISO 9001/ TS 16949/ISO 14001

Application: Auto

▪ Specialized in designing and manufacturing varies of progressive stamping dies.

▪ Improve the productation efficiency and introduce the new technology.

▪ Formulate SOP and complete production mechanism.

▪ With 50 members, our team have 8 senior engineers, 15 intermediate engineers, 23 assistant engineers and technician.

▪ Our team have more than 10 years experience in high speed precision electronic stamping die design and production. Perfect combination of individual and team is our consistent purpose