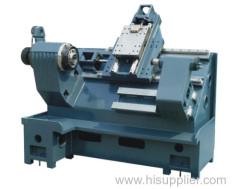

JASU 2-Axis Linear Guide Horizontal CNC Lathe Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 20sets/month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Guangzhou, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | CNC Machine |

Product Detail

| Model No.: | L-4075 |

|---|---|

| Means of Transport: | Ocean |

| Processing Types: | Metal |

| Processing: | Lathe |

| Automatic Grade: | Automatic |

| Workpiece and Weight: | Heavy-duty Machine Tool |

| Precision: | High Precision |

| Controlling Mode: | CNC |

| Usage: | Combined |

| Brand Name: | JASU |

| Production Capacity: | 20sets/month |

| Packing: | wooden case for export |

| Delivery Date: | 25days |

Product Description

Best Price For You

Very favourable price for you from $20000 to $40000(Prices vary from different configuration)

Agent Wanted For US

Warmly Welcome Your Joining In To Be Our Agent In Your Market.

Being our agent, more favourable price will be entitled, comprehensive before&after-sale service will be offered.

JASU L-4075 2-Axis Linear Guide Horizontal CNC Turning Center features:

1. Lathe Bed:

JASU L-4075 Turning Center bed is made by the advanced resin sand casting material, internal stress eliminated by special method. With the exquisite design, the bed has the excellent performance for machining and accuracy requirements;

2. Guide Rail:

JASU L-4075 CNC Lathe adopts the linear guide rail for X/Z axes, made by the advanced resin sand casting material, load ability improved;

3. Lead Screw:

High-precision and high-quality ball screw is adopted to make sure the positioning accuracy;

4. Spindle Motor:

High-performance motor make sure that the machine performs well at high/low speed and light/heavy cutting(7.5/11Kw);

5. Electrical Cabinet:

Heat exchanger is installed in electricity cabinet to guarantee the stable of system. Coiler is equipped outside the CNC Turning Lathe, it is heat, oil and water-resistant;

6. Lubrication System:

Automatic Centralized Lubrication System of JASU L-4075 CNC Lathe Machine can provide timely and accuracy lubrication according to the machine situation to enable the machine work continuously;

7. Controller: Advanced Fanuc, Mitsubishi and GSK controller for your choice.