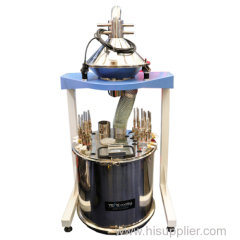

Ultrasonic vibrating sieve for coating powder

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 sets/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Xinxiang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Vibrating Screen, Feeder, Filter, Motor |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Application: | Others |

| Type: | Separator |

| Brand Name: | Gongwei |

| Application: | Food Processing |

| Certification: | ISO9001:2008 |

| Model Number: | WXZC |

| Screen size: | 5- 500 mesh |

| Usage: | screening,filtration |

| Material: | SS304/316lL and carbon steel |

| Voltage: | customized |

| Production Capacity: | 50 sets/month |

| Packing: | as your required |

| Delivery Date: | 10-15 days |

Product Description

Work principle

Ultrasonic Vibrating Screens are made up of ultrasonic controller, converter and resonance loop. Electric oscillation generated by the ultrasonic controller is converted by the converter into high frequency sinusoidal longitudinal oscillatory wave, which transfers to the resonance loop and create resonance and then goes uniformly onto the screen surface. Ultrasonic vibration is added to the low frequency rotating vibration of materials on the screen mesh, preventing mesh clog and enhancing the screen's productivity and quality.

Application

Ultrasonic vibrating screen is suitable for screening fine powder. It is widely used in silicon, alloy powder, tungsten powder, aluminum powder, rubbing powder etc.

Features

1. Ultrasonic self-cleaning function can prevent the sieve cloth of 50~625 mesh being plugged, and prolong the life span of sieve mesh.

2. Can exactly separate micro particles of similar size.

3. During work process, the machine temperature won't rise, suitable for sieving medicine powder and its original materials, thermosetting coatings and so on.

4. It can be used with single layer or multilayer. A set of intelligent ultrasonic generator can be used with three controllers at the same time.

5. This kind machine has the function of being able to effectively control the sieving granularity scale, which can realize the high precision sieving to achieve the best sieving effect.