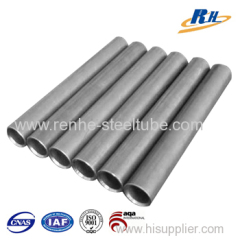

Cold Drawn Carbon Steel Tube

| Place of Origin: | Zhejiang |

|---|

Company Profile

| Location: | Tianjin, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Carbon Steel Tube, Seamless Carbon Steel Tube, Carbon Steel Hydraulic Tubing |

Product Detail

| Model No.: | RRT |

|---|

Product Description

Cold Drawn Tube , Carbon Steel Tube EN10305-1 E215 E255 , DIN2391 ST37.4

Specifications:

- OD:4-60mm,WT:0.5-60mm

- Standard:EN10305-1/4/DIN2391/C,DIN1630,BS6323/4,ASTM519,JIS G3445

- Delivery Condition:NBK(Bright annealing without oxidization)

- Length:5800mm,6000mm.

- Package:Bundles or wooden cases.

- Surface Anti-rust:Both outside and internal tube surface flushing with anti-rust oil.

- Surface quality:very smooth and bright without oxide scale,pock,strach,crack and other defects..

- Surface Cleaness:clean without iron scrap,dust,better for hydraulic system life.

- Mechanical Properties:Better extending rate and strength property,after bending with no deformation,after flattening and flaring process with no crack.

- Test:Tensile Strength Test,Flaring and flattening test,Hardness Test,Chemical Compositon Test

Description:

Synopsis of Process Routing: Quality Carbon steel — Cold Drawn — Heat Treatment Without Oxidization (NBK Status) — Nondestructive Testing— Flushing The Internal Hole With Special Equipment Under The High Pressure —Dealing With Antirust Oil On Surface — Plastic Capping On Both Ends.

The raw material we choosing:high quality Bao Steel,XingCheng Steel and HuaiSteel.Physical and chemical inspection will be made to make sure each batch is in qualified range. After piecing,each piece of tube is checked to be in permitted size deviation,this can garantee higher thickness tolerance and concentricity.

Production process quality control: We use the domestic first-class drawing machine,the production process is controlled with high hardness alloy internal and external matrix,so the product dimensions tolerance and ovality are strictly controlled in high level.Through the first, middle and last process inspection to ensure product quality.

Inner and Outer Surface Cleaning: We adopt automatic inner surface cleaning machine, rotating brush cleaning and high pressure oil flushing to clean the inner and outer surface.The new steel tube production craftsmanship can effectively remove a