machines to dig wells oilfield drill collar stabilizer

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 1000 pieces per month |

| Place of Origin: | Hebei |

Company Profile

| Location: | Cangzhou, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | TCI Tricone Bit, Steel Tooth Tricone Bit, Pdc Bit, Single Bit, Hole Opener |

Product Detail

| Model No.: | as you want |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Oil |

| Type: | Others |

| Brand Name: | Lockheed |

| name: | drill collar stabilizer |

| type: | as you want |

| size: | 3 3/4"-26" |

| warranty: | 2-3 years |

| brand name: | Lockheed |

| main market: | Europe,Middle East,USA,etc |

| transportation: | by sea or by air |

| packing information: | wooden case or as you want |

| payment term: | T/T |

| delivery time: | 5-10 days |

| Production Capacity: | 1000 pieces per month |

| Packing: | wooden case or as you want |

| Delivery Date: | within 5-10 days after your payment received |

Product Description

Cangzhou Lockheed Drilling Equipment Parts Co.,Ltd

1.Company profile

Established in 1998, Cangzhou Lockheed Drilling Equipment Parts Co., Ltd. is a professional technology-oriented enterprise specialized in the production drilling equipments and tools,which is one of the leading corporations of drilling tools and workover fishing tool manufacturing industry. Including three series with full model types,as follows:

Drilling Bit series: rock roller bit,tricone bit,pdc drill bit,single bit,cone bit and hole opener;

Drilling Equipment Parts series: manual tong,elevator,slips,stabilizer;

Workover Fishing Tool series: releasing spear,junk basket, overshot,reversing sub,die collar, fishing tap etc.

Our goal:Strive for Perfection and Win by Quality.

2.Product detail

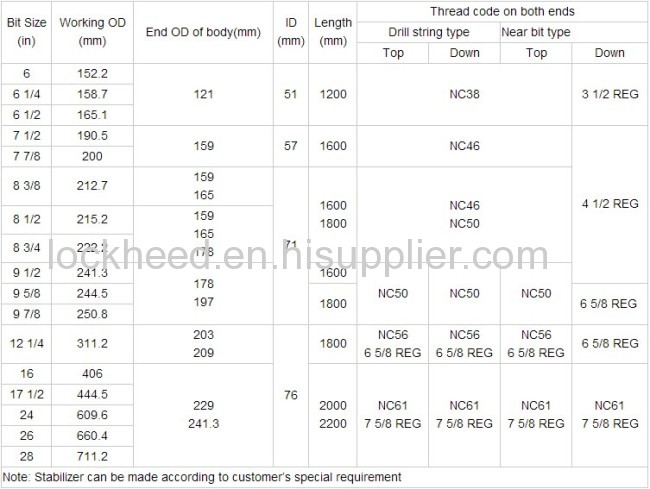

Drill collar stabilizer

1.Hole sizes range:6" to36" .

2 Type:string, near bit

3 Forge+Q&T+sprial+API connection+hardfacin

4.API Spec.

5.Factory directly

The stabilizer with back-reaming is selecting the appropriate location and through special processing method to array few teeth as a cutting edge. In this way, this stabilizer can be played cutting when the process of drilling and pull out. During drilling process, forward and backward redressing can be played the role to repair and maintain the wall of a well, making trajectory of borehole as far as possible, more often than not leading to drilling difficultly because of hole shrinkage, and so on, at the moment, the forward and backward redressing of this stabilizer can be played cutting, to eliminate hole shrinkage phenomenon, thus saving time and costs for drilling.

Features:

1.Providing stiffness and cerntralization above the pump

2.Improving pull and top cage run time on insert pumps

3.Minimizing pull rod buckling on insert pumps

4.Improving plunger performance in both insert and tubing pumps

5.Decreasing plunger top wear above the pump

6.Increasing minimum loads due to improved pump action

7.Improving pump performance in horizontal wells

8.Centralizing sinker bars

9.Minimizing contact between the sinker bar and tubing wall

3.Other drilling equipment show

4.Packing and transportation

5.Welcome to cantact me at any time!!!

Your satisfaction is our mission!!!