Aluminum Gravity Die Casting

| Min. Order: | 500 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 10000 Piece/Pieces per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Custom Gravity Casting Connection, Aluminum Alloy Auto Parts, Aluminium Alloy Hardware Parts, Aluminium Alloy Assembly Parts, Alloy Aluminium Sand Casting Parts |

Product Detail

| Model No.: | Hardware Accessory |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Model No: | KT-SC-103 |

| OEM service: | Available |

| Mould Life: | 80,000-10,0000 pcs |

| Surface Treatment: | Sand blasting |

| Material: | Aluminium Alloy |

| Weight: | 0.5-1 Kg |

| Standard: | ISO9001 |

| Heat Treatment: | T6 |

| Brand of Material: | A356 |

| Processing: | Gravity Casting |

| Production Capacity: | 10000 Piece/Pieces per Month |

| Packing: | as requirments |

| Delivery Date: | 45-50days |

Product Description

Product Name: Aluminum Gravity Die Casting.

Factory:

Ningbo Ketai Industry Co., Ltd. was established in 1991, Backed by China Weapon Reserch Institute Ningbo Branch. We have more than 20 years experience in Aluminum alloy casting area.

Good quality with low price, timely delivery.

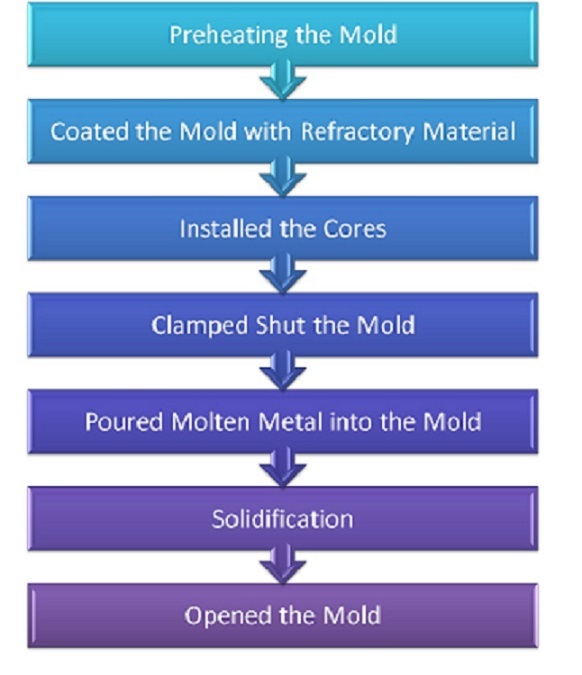

Gravity Casting:

The gravity process begins by preheating the mold to 150-200 °C (300-400 °F) to ease the flow and reduce thermal damage to the casting. The mold cavity is then coated with a refractory material or a mold wash, which prevents the casting from sticking to the mold and prolongs the mold life. Any sand or metal cores are then installed and the mold is clamped shut. Molten metal is then poured into the mold. Soon after solidification the mold is opened and the casting removed to reduce chances of hot tears.

We have produced more than 1500 different kinds of products, mainly per OEM, and more than 90% of the aluminum alloy castings are exported to the USA, Japan, Germany, Australia, Canada, Sweden etc.

Quality Assurance:

Based on our testing equipments bellow and strict quality control system, Universal inspection tools: Hardness tester, Height ruler, Depth ruler etc.

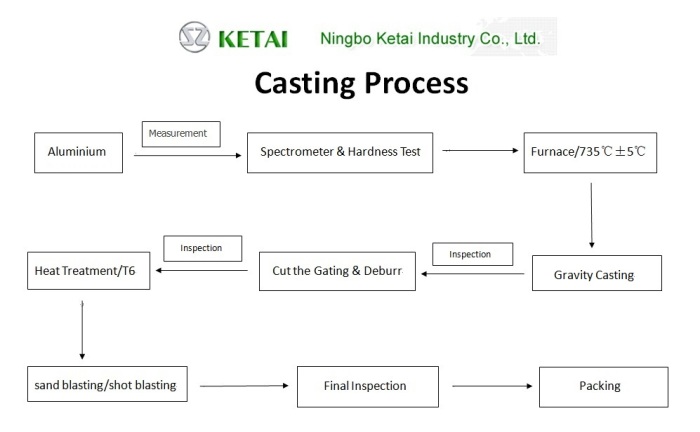

Casting Process:

Payment Terms:

1. Payment for tooling: pay 50% in advance ,and samples will delivery within 50days, after confirmed the samples pay the balance 50%

2. Payment for goods: Pay 30% in advance ,after deliver the goods ,see B/L copy pay the balance 70%.

Aluminiun Alloy List. Material is varity.

CHINA

GB/T 1173

INTERNATIONAL ATANDARD

ISO 3522

GERMANY

DIN 1725.2

ENGLAND

BS 1490

FRANCE

NF A57-105

JAPAN

JIS H5202

AMERICA

ASTM B179

ZAlSi7Mg(ZL101)

Al-SiMg(Fe)

G-AlSi7Mg

LM25

A-S7G

AC4C

356

ZAlSi7MgA(ZL101A)

Al-SiMg

G-AlSi7Mg

LM25

A-S7G

AC4C

356A

ZAlSi12(ZL102)

Al-Si12

G-AlSi12

LM20

A-S13

AC3A

413.2

ZAlSi9Mg(ZL104)

Al-Si10Mg

G-AlSi9Mg

__

A-S9G

AC4A

359

ZAlSi5Cu1Mg (ZL105)

Al-SiCu1Mg

G- AlSi5Cu

LM16

__

AC4D

355

ZAlSi5Cu1MgA(ZL105A)

Al-Si5Cu1Mg

G- AlSi5Cu

LM16

__

AC4D

355.2

ZAlSi8Cu1Mg (ZL106)

Al-SiMg(Fe)

__

LM24

A-S7G

AC4B

328.1

ZAlSi7Cu4(ZL107)

Al-Si6Cu4

G- AlSi6Cu4

LM21

__

AC2B

319.2

ZAlSi12Cu2Mg1 (ZL108)

Al-Si12Cu

G-Al Si12(Cu)

LM13

A-S13

AC3A

383.2

ZAlSi12Cu1Mg1Ni1(ZL109)

Al-Si12Cu

G-Al Si12(Cu)

LM13

A-S13

AC3A

A413

ZAlSi5Cu6Mg (ZL110)

Al-Si16Cu4

G- AlSi6Cu4

LM21

__

__

308

ZAlSi9Cu2Mg (ZL111)

Al-Si10Mg

G- AlSi8Cu3

LM2

A-S9G

AC4B

354

ZAlSi7Mg1A(ZL114A)

Al-Si7Mg(Fe)

G-AlSi7Mg

LM25

A-S7G-03

AC4C

357

Welcome to view & scan our website and build business relationship with us. Your feedback will be highly appreciated.

.jpg)

.jpg)

.jpg)